Product Description:

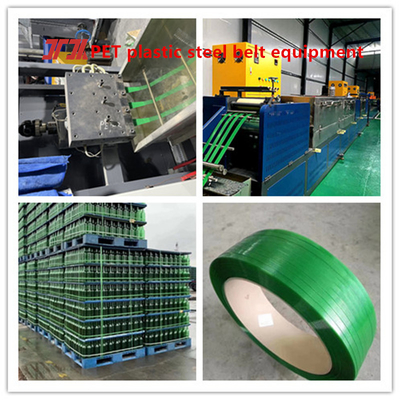

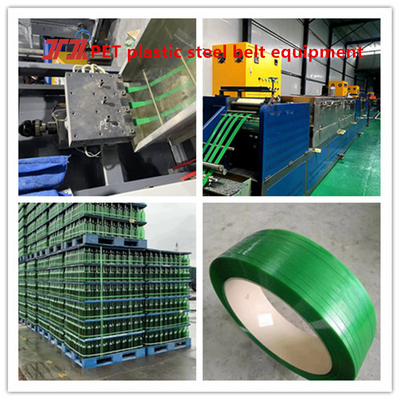

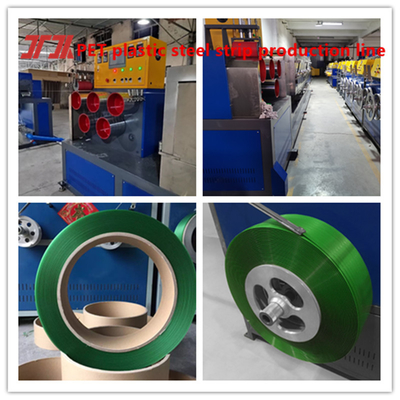

1. Discover the future of eco-friendly manufacturing with our PET strapping production line equipment, meticulously engineered to align with stringent environmental protocols. Harness the power of recycling by transforming waste bottles, like those from mineral water and popular sodas, into high-quality PET plastic steel straps. This state-of-the-art equipment features an advanced computer control system, allowing seamless real-time adjustments of melt temperature, pressure, extrusion speed, torque, and traction, ensuring consistent premium product quality every time.

2. Experience unparalleled precision with our dual shaping systems-stretch shaping and dual-phase shaping-offering unmatched flexibility and control. This comprehensive equipment suite includes: stirring, feeding, drying, dehumidification, an advanced main machine, cooling, extension, shaping, small and large traction units, embossing, and a sophisticated winding machine, all designed for optimal performance and efficiency.

3. The dynamic PET plastic steel strap equipment offers versatile production capabilities, accommodating widths from 9mm to 32mm and thicknesses from 0.4mm to 1.2mm, catering to diverse industrial needs.

Features:

- Product Name: PET Strap Making Machine

- Capacity: 300-500KG/H

- Strap Width :9-32mm

- Strap Thickness: 0.6-1.2mm

- Raw material: PET Bottle Flake Material, 100% Broken Material

- Weight: 21000KG

- Power: 45KW

- Honeycomb rotary dehumidification dryer: 0ST-1000

- The equipment voltage : Three-phase 380v/50Hz

- Equipment footprint: (L)65*(W)3.0*(H)8M

Technical Parameters:

| Name |

PET Plastic Steel Belt Production Equipment |

| Final product |

PET Packing Strap Belt |

| Strap Width |

9-32mm |

| Strap Thickness |

0.6-1.2mm |

|

Main machine bucket

|

3000-5000L |

|

Pre drying towe

|

3000-5000L |

| Weight |

21000KG |

| Winding method |

Manual/automatic |

| Solid-state relay |

Taiwan Fotek |

| Paper core diameter |

Ø406*150mm |

Applications:

1. The heart of our PET strapping production line, the extruder, utilizes a PET-specific screw with a revolutionary parameter design. This innovative screw ensures superior raw material plasticization through its unique separation and mixing effects. Enjoy the benefits of substantial extrusion capacity, exceptional plasticization quality, increased hardness, and remarkable wear resistance.

2. Revolutionize your filtration process with our three-dimensional folding ultra-large area filter device, offering a filtering mesh area 30 times larger than conventional flat filters. Capable of reaching up to 80 meshes, this unique screen-changing device drastically reduces downtime, significantly boosting operational efficiency.

Support and Services:

The PET Strap Making Machine is a durable and reliable machine that is designed to produce high-quality PET straps. Our technical support and services team is available to assist you with any questions or concerns you may have about the machine.

We offer the following support and services for the PET Strap Making Machine:

- After-sales service:

1. Water and electricity lines, circuit diagrams, etc. of PET tape making machines.

2. Installation, commissioning and training of PET tape making machines.

3. Maintenance services of PET tape making machines.

4. Regular maintenance and repairs

5. Fault diagnosis

6. Software updates and upgrades

7. Spare parts and accessories

8. Training and technical consultation

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews