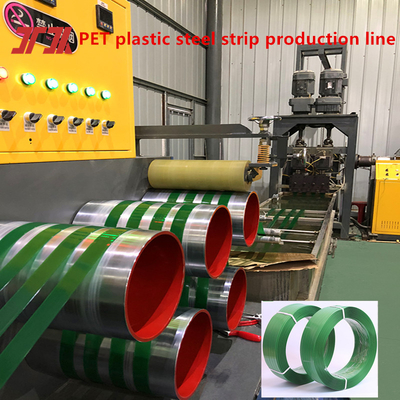

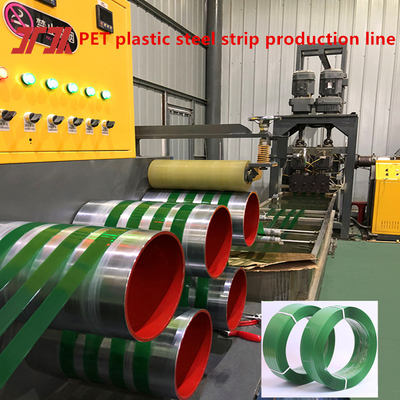

High-end intelligent PET plastic steel belt equipment PET plastic extrusion equipment 9-32mm width

Product Description of PET plastic steel belt equipment:

1. Discover the eco-friendly PET strapping production line equipment, designed to align perfectly with environmental standards. Transform waste materials like mineral water, Sprite, and Coke bottle flakes into high-quality PET plastic steel straps effortlessly. Our cutting-edge machinery features an advanced computer control system that meticulously manages melt temperature, pressure, extrusion speed, torque, and traction in real time, ensuring unmatched consistency in product quality with every operation.

2.Our PET plastic steel belt equipment is advanced in technology and equipped with metering pumps, melt pumps, etc. to enhance the overall performance of the machine. The system includes key components such as stirring, feeding, drying, dehumidification, main machine extrusion melting, cooling, stretching, molding, large traction and embossing. This comprehensive configuration ensures excellent production efficiency and precision at every stage.

3. Our state-of-the-art PET plastic steel strap equipment is engineered to produce straps with a width range of 9-32mm and thickness of 0.4-1.2mm, offering versatility to meet diverse application needs.

Features of PET plastic steel belt equipment:

- Product Name: PET Strap Making Machine

- Strap number: 2-8 Straps

- Raw material: PET Bottle Flake Material, 100% Broken Material

- Switchgear: Schneider

- Paper tube size: GUOMAO

- Power: 45KW

- Dryer capacity: 3000L

- Pre drying tower: 5000L 1

- Honeycomb rotary dehumidification dryer:0ST-1000

Technical Parameters of PET plastic steel belt equipment:

| Product Name |

PET Plastic Steel Belt Production Equipment |

| Weight |

21000KG |

| Wrapping machine |

Automatic or semi-automatic winding |

| Strap Number |

2-8 Strap |

| Paper Core Diameter |

Ø406*150mm |

| Host Inverter |

45KW(INVT) |

| Screw |

100*2900mm |

| Speed |

120-250m/min |

| Warranty |

1 Year |

Applications:

1)Screw-----------Special screw for PET extruder, with the advantages of large extrusion volume, good plasticization, high hardness and high wear resistance;

2)Cooling system-----unique circulating cooling technology and multiple sets of shaping guide rails make the strapping belt cool, shrink and shape more fully, the product more stable and the size more accurate.

3)Five-roller traction system-------stable traction, smooth equipment operation, and reduced failure rate

4) Linear speed----------More than 100-150 meters per minute

5)PLC---------PLC computer control system, instead of potentiometer to control speed regulation, can memorize production parameters, and the operation is more convenient

Support and Services:

Our PET plastic steel belt equipment provides comprehensive technical support and services. Our experienced team of technicians can provide a variety of services, including:

Pre-sales:

1. PET belt making machine layout diagram.

2. PET belt making machine cost analysis.

3. Raw materials that can be used for PET belt making machine.

After-sales service:

1. Water and electricity lines, circuit diagrams, etc. of PET belt making machine.

2. Installation, commissioning and training of PET belt making machine.

3. Maintenance service of PET belt making machine.

4. Regular maintenance and repair

5. Fault diagnosis

6. Software update and upgrade

7. Spare parts and accessories

8. Training and technical consultation

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews