pet strap manufacturing machine 100-600KG/H PET plastic steel strap production line PLC control system

Product Description of pet strap manufacturing machine:

PET Strap Making Machine

This latest process PET belt making machine can meet the width: 9-32mm PET packaging belt, thickness: 0.6-1.2mm, it provides special strength and durability for your packaging needs. The machine has a variety of features, including manual and automatic winding options, 2-8 strip counts, and high-speed 180-260m/min.

The PET Strap Making Machine is equipped with the latest technology to ensure superior performance and user-friendly operation. The machine comes with a memory parameter function, allowing you to save your preferred settings for future use. It also features SIMENS control system, which offers precise control and monitoring of the machine. The double cylinder and single cylinder options provide added flexibility for different production needs. The touch screen interface makes it easy to operate and monitor the machine, while the automatic alarm system alerts you in case of any issues.

The PET Strap Making Machine is a high-quality and efficient solution for all your strapping needs. With its advanced technology and key features, it offers exceptional performance and productivity. Whether you need to produce a small or large number of straps, this machine can handle it all.

EXTRUSION PARAMETERS TABLE

| Model |

PET-2 |

PET-3 |

PET-4 |

PET-6 |

PET-8 |

| Raw materials |

100% Bottle flakes/crushed materials |

| Number of tapes |

2 |

3 |

4 |

6 |

8 |

| Width (mm) |

9-32 |

| Width (mm) |

0.4-1.2 |

| Maximum line speed(m/min) |

≧150 |

≧150 |

≧150 |

≧150 |

≧150 |

| PLC control system |

PLC |

PLC |

PLC |

PLC |

PLC |

| Screw Model |

90 |

100 |

125 |

150 |

180 |

| Reducer model |

200 |

250 |

280 |

315 |

350 |

| Dryer tank |

3000L |

4000L |

5000L |

6000L |

6000L |

| Dehumidifier |

1000 |

1000 |

2000 |

3000 |

3500 |

| Metering Pumps |

100CC |

100CC |

100CC |

100CC |

100CC |

| Screen Changer |

Single cylinder |

| Winding machine |

Automatic winding/ Semi-automatic winding |

| Production capacity /24 H |

5-6T |

7-8T |

10-12T |

12-15T |

18-20T |

Our customization options include:

- Adjusting the final product specifications to fit your desired PET packing strap belt size and shape

- Using 100% recycled bottle flakes material for a more sustainable production process

- Addition of specialized features for specific industry needs

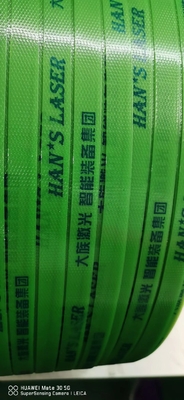

- Customized branding options

- And more

With our PET Strap Making Machine, you can be assured of high-quality, durable, and efficient production of PET straps. Contact us now to discuss your customization requirements and get a quote.

Packing and Shipping:

Packaging and Shipping for PET Strap Making Machine

The PET Strap Making Machine will be carefully packaged and shipped to ensure it arrives to you in the best condition possible. Our packaging process follows industry standards to ensure the safety and security of the machine during transportation.

Packaging Process

1. The PET Strap Making Machine will be carefully inspected and cleaned before packaging.

2. The machine will be disassembled into smaller parts to facilitate safe and efficient packaging.

3. Each part will be wrapped with protective materials, such as bubble wrap and foam, to prevent any damage during transportation.

4. All parts will be placed in a sturdy wooden crate to prevent shifting during transit.

5. The crate will be sealed and labeled with handling instructions and a fragile sticker.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews