TAutomatic winding PLC control PET PET belt extrusion equipment 300-350KG/H

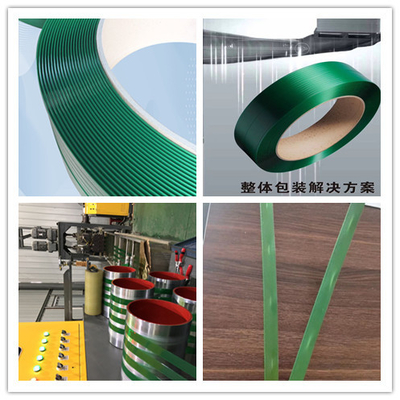

Product Description of pet strap manufacturing machine:

Features :

1. Adopt special PET extruder dedicated screw, extrusion energy can be customized according to customer requirements.

2. Can use 100% recycled PET bottle flakes or broken material pellets for production.

3. The main machine extrudes evenly, the die head flow channel extrudes stably, and the whole line is automatically controlled by PLC.

4. According to different requirements, the coating material is replaced to make the strap have better stretching ability.

5. Equipped with melt filter, ventilation design and backwashing function.

6. Number of straps: 1-8 straps, support customization.

Features of pet strap manufacturing machine:

- Product Name: PET Strap Making Machine

- Host inverter: INVT

- Automatic winding: YES

- Switchgear: Schneider

- Speed: 200-260m/min

- Paper tube size: GUOMAO

- Screw:Ø100*2800mm

- Discharge port: 4 strips from one die head

- Screen changer:Double cylinder / single cylinder

- pet strap manufacturing machine

- pet strapping band making machine

- pet strap extrusion line

Technical Parameters of pet strap manufacturing machine:

PET plastic steel strip specification table

| Model |

Width |

Thickness |

Pull |

Gross weight |

net weight |

net weight |

Length |

| PET-0950 |

9.0mm |

0.50mm |

>150kg |

20kg |

18.5kg |

200/406mm |

3400m |

| PET-1050 |

10.0mm |

0.50mm |

>180kg |

20kg |

18.5kg |

200/406mm |

2720m |

| PET-1250 |

12.0mm |

0.50mm |

>210kg |

20kg |

18.5kg |

200/406mm |

2500m |

| PET-1260 |

12.0mm |

0.60mm |

>220kg |

20kg |

18.5kg |

200/406mm |

2300m |

| PET-1360 |

13.0mm |

0.60mm |

>250kg |

20kg |

18.5kg |

200/406mm |

1850m |

| PET-1660 |

16.0mm |

0.60mm |

>320kg |

20kg |

18.5kg |

200/406mm |

1480m |

| PET-1670 |

16.0mm |

0.70mm |

>370kg |

20kg |

18.5kg |

200/406mm |

1270m |

| PET-1680 |

16.0mm |

0.80mm |

>450kg |

20kg |

18.5kg |

200/406mm |

1080m |

| PET-1610 |

16.0mm |

1.00mm |

>520kg |

20kg |

18.5kg |

200/406mm |

970m |

| PET-1970 |

19.0mm |

0.70mm |

>0kg |

20kg |

18.5kg |

200/406mm |

1020m |

| PET-1910 |

19.0mm |

1.00mm |

>700kg |

20kg |

18.5kg |

200/406mm |

740m |

| PET-1912 |

19.0mm |

1.20mm |

>850kg |

20kg |

18.5kg |

200/406mm |

660m |

Support and Services :

We provide a full range of technical support and services for our PET Strap Making Machine. Our team of experts are always available to answer any questions you may have, help troubleshoot any issues, and provide technical advice to ensure that you get the most out of your machine. Our comprehensive service package includes:

- Regular maintenance and inspections

- Repair and replacement of components

- Software updates and upgrades

- On-site technical support

- Remote technical support

- Training and educational resources

We understand that a reliable technical support and service package is essential for getting the most out of your PET Strap Making Machine. Our team of experts are ready to help you maximize your machine’s performance and efficiency.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews