Automatic winding PLC control PET PET belt manufacturing equipment 300-350KG/H

Product Description of PET strap making machine:

►The PET Strap Extrusion Line is a high-performance PET strap making machine for producing PET straps from PET-130 materials. It features a Siemens 37KW main motor and a paper core specification of ¢406*150mm, along with a strap width range of 9-32mm and a line speed of 220-260m/min. This PET strap production line is manufactured to the highest standards, ensuring superior quality and optimal performance in PET strap production. It is suitable for a wide range of applications, from packaging and strapping to other industrial and commercial uses. The PET Strap Extrusion Line is a reliable, cost-effective choice for any business looking to produce PET straps in an efficient and effective manner.

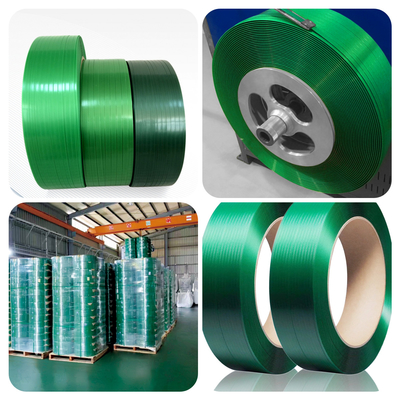

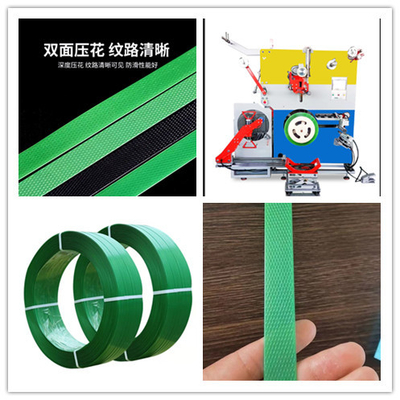

►PET packaging belt, also known as plastic steel belt, is a new type of binding belt that is currently popular in the world instead of iron belt, widely used in steel, aluminum, chemical fiber, cotton spinning, brick factory, paper industry, metal can and other industries. Strong tensile strength: both the tensile strength of steel strip, and the ductility of impact resistance, to ensure the safety of your products.

Features of PET strap making machine:

- Product Name: PET Strap Extrusion Line

- Raw material:PET bottle flake material, 100% broken material

- Advanced technology: YES

- Width:9-32mm

- Strap Thickness: 0.6-1.2mm

- Winding method: manual/automatic

- Extrusion Capacity: 400-4500KG/H

- Reducer specification: 280#

- Number of tapes: 4

- Keywords: PET Strap Production Line, PET Strap Manufacturing Line, PET Strap Making Machine

Technical Parameters:

| Parameters |

Value |

| Name |

PET packaging belt production line

|

| Strong and Durable |

Yes |

| Host Inverter |

37kw (INVT) |

|

Main motor

|

37KW(Siemens)

|

| Number of Tapes |

4 |

| Equipment Footprint |

L60*W2.0*H7.0M |

| Extrusion Capacity |

400-4500KG/H |

|

Operation mode

|

PLC computer touch screen

|

| Honeycomb Rotary Dehumidification Dryer |

0ST-2000 |

| Neat Winding |

Yes |

| Pre Drying Tower |

4000L |

|

Material tank

|

4000L |

| Material |

PET-100 |

Applications of PET strap making machine:

JIATUO CHINA’s PET Strap Extrusion Line is the perfect solution for PET strap production. With CE SGS ISO certification, this extrusion equipment is designed to meet the highest standards of quality and reliability. The JTPET model is capable of producing PET straps with a thickness ranging from 0.6mm to 1.2mm. The extrusion line offers both manual and automatic winding options, and comes with one set of oil removal and dust removal filter and four sets of double position winder. The 75kw host inverter (INVT) ensures a smooth and efficient operation. The minimum order quantity is one set, and the delivery time is typically 50-60 days.

Customization of PET strap making machine:

JIATUO CHINA PET Strap Extrusion Line

Model Number: JTPET

Place of Origin: CHINA

Certification: CE SGS ISO

Minimum Order Quantity: 1 SET

Delivery Time: 50-60 Days

Pre drying tower: 5000L

Line Speed: 220-260m/min

Neat winding: YES

Strap Thickness: 0.6-1.2mm

Strap Tension: >10000kg

Keywords: PET Strap Making Machine, PET Strap Manufacturing Line, PET Strap Manufacturing Line

Support and Services of PET strap making machine:

We provide comprehensive technical support and service for PET Strap Extrusion Line. Our professional technical team is available to help customers with troubleshooting, maintenance, technical advice and repair services. We also provide training services to ensure customers can operate and maintain the equipment properly and safely. Our after-sales service team is available 24 hours a day, 7 days a week to provide quick response and timely solutions to customers' troubles. In addition, we also provide spare parts, components and consumables for long-term stability and reliability of the equipment.

Packing and Shipping of PET strap making machine:

Packaging and Shipping for PET Strap Extrusion Line:

The PET strap extrusion line is safely packaged in a wooden crate with protective foam inside. The crate is then strapped and sealed, ready for shipping.

The PET strap extrusion line will be shipped via LCL sea freight, FCL sea freight, air cargo, or express delivery, depending on the customer's preference.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews