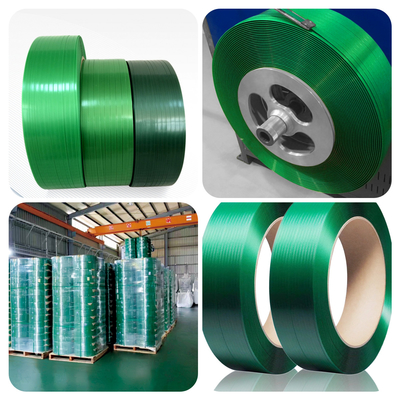

Packaging machinery 9-32mm PET plastic steel belt production line PET extrusion equipment for chemical fiber filter

Product Description of PET strap production line:

1.The extruder uses a special PET screw with unique parameter design. The screw has a unique separation and mixing effe ect to ensure the uniform plasticization of the raw materials. It has the advantages of large extrusion, good plasticization,high hardness, high wear resistance, etc.

2.The three-dimensional folding super !arge area filter device, the unfolded area of the filter screen is 30 times larger than tl the area of the traditional flat filter screen; the filter mesh can reach 80 meshes, and the unique screen changing device greatly reduces the screen changing time and improves work efficiency.

3.The rotating honeycomb dehumidification drying system is used to dry the raw materials.

4.The dew point of -50°C ensures that the moisture content of the raw materials is ≤50PPM, and has the effect of solid-pha ase polycondensation and viscosity increase.

stable, and the width and thickness fluctuations are much smaller than national standards;

5.The equipment adopts a unique double-stretching process, which has good rigidity and stable width, which improves the t tensile strength of the finished product.

6.High-precision components make the product quality Unique oven circulating heating system, internal reciprocating winding method, making full use of heat energy to

greatly r reduce power loss.

7.ToThe unique circulating cooling system and multiple sets of shaping guide rollers make the packing belt cooler and shrinl nk more fully, the product is more stable, and the size is more accurate.

8.ToThe five-roller traction system has stable traction, makes the equipment run smoothly, reduces the failure rate, and red duces the post-maintenance cost by 60%.

9.ToThe high-precision special embossing and pressing device, the pressure is adjustable, the embossing wheel can be sy ynchronized up and down, the embossing is clear and beautiful, and the product quality is comparable to that of Europe, America, Japan and South Korea.Constant force rewinding system, unique design paramet ters, in line with high output, excellent reeling effect, flat and beautiful sides on both sides.

10.The rewinding machine adopts double-station rewinding device, which is easy to operate and easy to change the reel.

11.It can be produced entirely with 100% bottle flakes, and the quality of the finished product can be compared with brand ne ew materials.

Main features of PET steel plastic belt equipment:

Efficient production: PLC control, high degree of automation, fast production speed.

High-quality products: The produced plastic steel belt has high strength, good toughness and corrosion resistance.

Energy saving and environmental protection: using advanced technology, low energy consumption and high output.

Easy operation: The equipment is automatically wound, simple to operate and easy to maintain.

About automatic winding machine:

Suitable for 9-32mm width PET plastic steel strap, can be measured by meter, weight, two modes, free to switch.

The surface of PET plastic steel strap is integrated, wound in an orderly manner, without overlapping.

The weight can reach 20-350KG/roll.

Line speed: 120-200 m/min

EXTRUSION PARAMETERS TABLE

| Name |

PET Plastic Steel Belt Production Equipment |

| Strap Material |

PET Plastic Steel Belt |

| Control system |

PLC |

| Winder |

Manual/automatic |

| Width |

9-32mm |

| Thickness |

0.4-1.2mm |

| Strap Speed18 |

0-220m/min |

| Motor Power |

45KW (Siemens) |

| Screw |

90*2800mm 100*3000mm (38CrMoALA) |

| Raw Material |

PET Bottle Flake Material, 100% Broken Material |

| Extrusion capacity |

100-600KG/H |

About PLC system:

The machine is equipped with a PLC control screen, which can display the parameters, frequency, speed, etc. of the whole machine.

And PLC has memory parameters and can save 99 different specifications at the same time (including production speed, frequency of each zone, model of mold used, etc.). The next time the same specification is produced, you only need to call out the saved model without repeated debugging, saving labor and manufacturing costs.

FAQ:

- Q: What is the brand name of the PET Strap Making Machine?

- A: The brand name is JIATUO CHINA.

- Q: What is the model number of the PET Strap Making Machine?

- A: The model number is JTPET.

- Q: Where is the PET Strap Making Machine from?

- A: The PET Strap Making Machine is from China.

- Q: What is the certification of the PET Strap Making Machine?

- A: The certification of the PET Strap Making Machine is IS CEO.

- Q: What is the minimum order quantity for the PET Strap Making Machine?

- A: The minimum order quantity is 1 SET.

- Q: What is the price of the PET Strap Making Machine?

- A: The price is negotiable.

- Q: How is the PET Strap Making Machine packaged?

- A: The PET Strap Making Machine is packaged with plastic film.

- Q: How long is the delivery time for the PET Strap Making Machine?

- A: The delivery time is 30-40days.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews