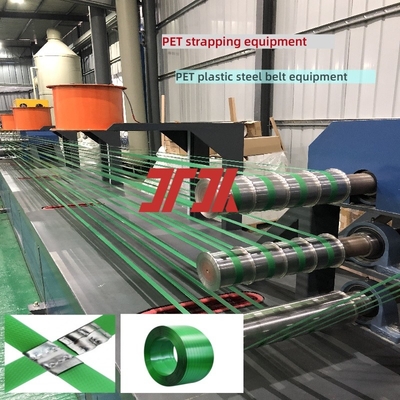

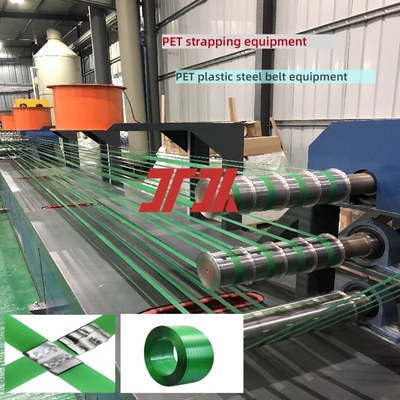

Product Description of PET plastic steel belt production equipment:

PET plastic steel belt production line features:

Extrusion process-----PET belt making machine uses a special screw for extruder, which is evenly extruded by heating and melting.

Cooling and solidification----The extruded PET belt embryo is then cooled and solidified using a cooling water tank or other refrigerator to ensure that the material maintains its shape and characteristics.

Stretching and orientation----PET belt making machines usually include stretching and orientation parts to improve the tensile strength, flexibility and overall performance of the PET belt. This process aligns the molecules in the PET material to enhance its mechanical properties.

Features of PET plastic steel belt production equipment:

- Product Name: PET Strap Making Machine

- Production Capacity: 400-600kgs/H

- Motor: SIEMENS Brand

- Strap Speed: 220m/min

- Voltage: 380V 50HZ 3Phase (Customized) 220V/440V

- Strap Color: White/Black/Blue/Green Etc.

- Numbers of straps: 4straps

- PLC Control System:1set

- Grooved:48sets

- Gear: 24sets

- Mold: 5 sets

- Double position winder:4sets

- PET packaging belt production line

- PET packing equipment

- Production equipment of bottle packaging tape

- Pack and tape equipment

Technical Parameters of PET plastic steel belt production equipment:

| Parameter |

Value |

| Product Name |

PET Strap Making Machine |

| Strap Speed |

150-220m/min |

| Strap Thickness |

0.4-1.2mm |

| Strap Width |

9-32mm |

| Strap Material |

PET |

| Strap Tension |

400-450kg |

|

Numbers of straps

|

4 straps

|

|

Gearbox model

|

280 type

|

|

screw

|

130*3900mm |

|

motor power:

|

75kw |

|

host frequency converter

|

75kw |

|

otal equipment power

|

300kw |

|

Equipment footprint

|

65*3.0*8M

|

Automatic PLC Controlled Double-Position PET/PP Strap Winder

Automatic PLC controlled single station PET/PP tape winder, this PP PET winder is suitable for tapes with extrusion speeds up to 180-250 m/min. Each machine is equipped with a reel. The machine is equipped with a reinforced tension arm to control the winding tension. The inclinometer fixed on the reinforced tension arm converts the physical position signal of the tension arm into an electrical signal and sends it to the programmable logic controller (PLC). After data processing, the PLC controls the running speed of the winding motor and drives the paper tube fixed on the winding shaft to evenly wind the tape with constant tension.

The winding process does not require manual operation, and there is no need to replace the transmission gear.

Automatic winding, automatic rewinding, automatic stop, and automatic roll change.

Services :

After-sales service

Our PET plastic steel belt equipment provides comprehensive technical support and services. We have an experienced technical team that can quickly provide a variety of services, including:

Pre-sales:

1. Layout of PET plastic steel belt equipment.

2. Analysis of finished product manufacturing costs of PET plastic steel belt equipment.

3. Analysis of raw materials used in PET plastic steel belt equipment.

After-sales service:

1. Waterway diagram, circuit diagram, pipeline connection drawings, etc. of PET plastic steel belt equipment.

2. Installation, commissioning and training of PET plastic steel belt equipment.

3. Maintenance service of PET plastic steel belt equipment.

4. Regular maintenance and repair

5. Fault diagnosis

6. Software update and upgrade

7. Spare parts and accessories

8. Training and technical consultation

FAQ:

- Q: What is the Brand Name of this PET Strap Making Machine?

A: The Brand Name is JIATUO CHINA.

- Q: What is the Model Number of this PET Strap Making Machine?

A: The Model Number is JTPET.

- Q: Where is this PET Strap Making Machine made?

A: This PET Strap Making Machine is made in CHINA.

- Q: What is the Certification for this PET Strap Making Machine?

A: This PET Strap Making Machine has IS CEO Certification.

- Q: What is the Minimum Order Quantity for this PET Strap Making Machine?

A: The Minimum Order Quantity is 1 SET.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews