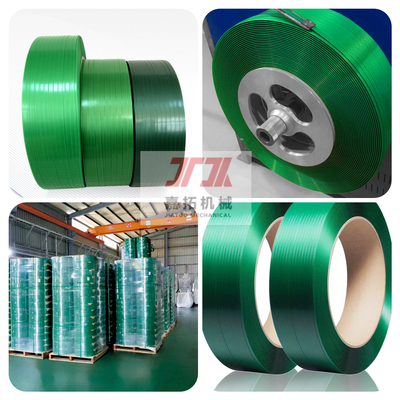

Electric PET Strap Making Machine 16mm Brick Kiln PET Bottle Recycled Flakes Packing

PRODUCT DESCRIPTION

Pet packing belt one out two production line equipment:

Pet belt (commonly known as plastic steel belt) is a new type of binding belt which is currently popular in the world to replace steel belt. It is widely used in steel, aluminum, chemical fiber, cotton spinning, paper industry, wood industry, building materials, metal products and other industries.

PET Strap Production Line Machine List

| NO. |

Item |

Specification |

| 1 |

Power |

According to customer's factory voltage |

| 2 |

Material |

PET raw material or 100% PET bottle flakes recycled |

| 3 |

Capacity |

PETJT90:200kg/h

PETJT100:250kg/h

PETJT125:350kg/h

|

| 4 |

Product size |

Width:9-32mm

Thickness:0.6-12mm

|

| 6 |

Mid-height of extruder |

7000mm |

| 7 |

Installation power |

PETJT90:200KW

PETJT100:250KW

PETJT125:300KW

|

| 8 |

Humidity |

<85% |

| 9 |

Temperature |

0-40 degree |

| 10 |

Cooling tower capacity |

30T/H or 50T/H |

| 11 |

Installation Dimensions |

PETJT90:45*2.0*7.0M

PETJT100:45*2.0*7.0M

PETJT125:60*3.0*8.0M

|

| 12 |

Product color |

Green/Black/Pink/Yellow |

| 13 |

Factory dimension |

35m*(3~6)m*(4~6)m

45m*(3~6)m*(4~6)m

If your factory not big enough,please contact with us,our engineer can according to your size to design

|

Advantages of Plastic Strapping

- Savings : Polyester's unique qualities make it one of the best strapping materials to use for securing any type of palletized or unitized load

- Proven Performance : Open top and cosed rail car shipments of Brick,Lumber and other panel products.

- Ease of Disposal : Polyester strapping can be easily disposed of by rolling or bending.then recycled

- Elongation Recovery : Polyester strapping provides approximately 2% elongation at normal work tension,which a;llows the materials to stretch.the strapping will recover this elongation however,keeping the strapping tight around the pacakge even if the load settles and shrinks in size.

- Moisture and UV Resistant : Because it is plastic,it is moisture resistant and therefore unaffected by rusting that might occur with other packaguing alternatives which may stain or affect the quality of your product before it gets to its destination. it is also UV resistant to protect strapping from long periods of exposure to the sun.

PET and PP strap making machine introduction

- Pre crystallization drying unit

As PET is easy to absorb moisture in the air, it must be fully dried. At the same time, in order to prevent bonding during drying, crystallization equipment needs to be configured. PP strap not need it.

Always PET two straps extrusion needs 90/30 single screw extruder.

PP two straps extrusion needs 75/30 single screw extruder.

Special design screw structurer could extrude PET PP materials smoothl,it does not create excessive shear molecular structure, and ensures the strength of the packing belt

- Filter, Melt Pumb, Exrusion Die Unit

It is controlled by PLC pressure closed loop control system. The pressure sensor will transmit signals, and PLC is used to control the speed of melt pump and extruder, so as to stabilize the extrusion of PET or PP materials

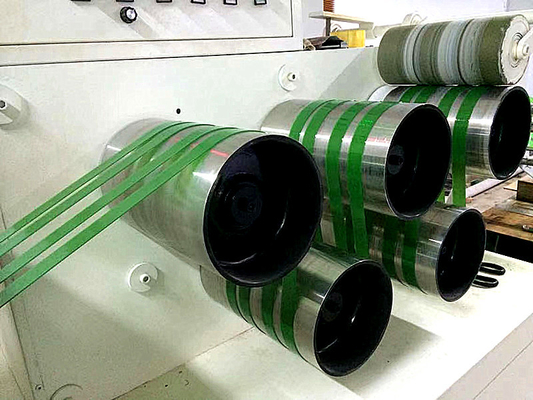

- Water tank with first haul off rollers

PET is Length 4000mm, PP 2000mm.

It is stainless steel materials.

The water is heated by water tank heating unit

The haul off rollers is five rollers, working to take PET or PP strap materials out of water tank

The oven is heated by electric power. Heating air is spread evenly by fans.

In the oven, the PET and PP strap will be stretched first time.

This device is working for PET strap second time stretching.

PP strap not need stretching.

This 38Crmoal materials, high surface hardness rollers do embossing

- Annealing oven and cooling tank

As PET and PP materials has high deformation prestress after stretching. It has to do annealing and water cooling to fix the size.

It is working to take the materials out of annealing oven and cooling tank before winders

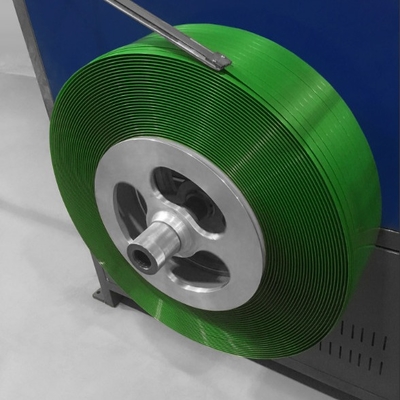

The winder could be designed into servo motor unit, inverter motor unit and torque motor according PET or PP materials.

The unique back tooth shaft is used to make the packing belts neatly arranged without overlapping and no horn shape, so that the packing belts maintain a good straightness, which is more suitable for the use of automatic packing machines, and ensures that the automatic equipment conveyor belts are in place. Do not drop the belt.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews