High Efficiency PET PP Packing Strap Making Machine 5-32mm Width

Product Description

PET PP Strap Extrusion Production Line

PET PP packing strap production is a new model of packing material machine, applying to advanced technology overseas. PET packing strap is the best replacement for old packing material, and is accepted in word packing industry. Nowdays, the PET PP packing strap hasebeen widly used in many industry such as paper steel, chemical fiber, cotton, printing wood and so on.

Descripition

This machine is mainly used to make PET strap ,PP packing strap.

Our machines adopts the PLC control to realsize the whole line auotmatic production.

Using the melting pump and pressure sensor ensure the production stable and strap quality control.

The raw material can be 100% recycled pet flakes from the waste pet bottles,or virgin material or mixed with each other.

Advantage

PP PET strap production line

1.Use 100% Recycled PET/PP Flakes to reduce the cost.

2.Good dehumidifer drying system(Crystallization system optional ) to ensure the material equal dryer to produce high quality strapping.

3.Special design hot forming tensile tank to make good forming ,equal width,straight strap.

Function

PP PET packing straps extrusion machine

1) PP PET raw materials do not need to separate the dry and water treatment . There are automatic circulation on preheating and drying that save a large number of equipment investment and reduce the production cost by 30%;

2) Utilizing the retrieving bottle slice as raw materials that reducing the cost to a great extent;

3) With the multi-purpose machine, produce the PP PET straps in different specifications directly and dont need to change the mould head;

4) Comparing with new polyester slice, the transparency of products is just the same, but the tensile strength and shock resistance are up to the international grade;

5) Low Energy consumption, but high production capability;

6)Easy to operate, save the manpower and two persons for one production line on average.

Machine parameter

PP melt making machine

| 1 |

Vacuum feeder |

| 2 |

Hopper dryer |

| 3 |

Feeding machine |

| 4 |

Extruding Machine |

| 5 |

Automatic Screen filter changer |

| 6 |

Mould |

| 7 |

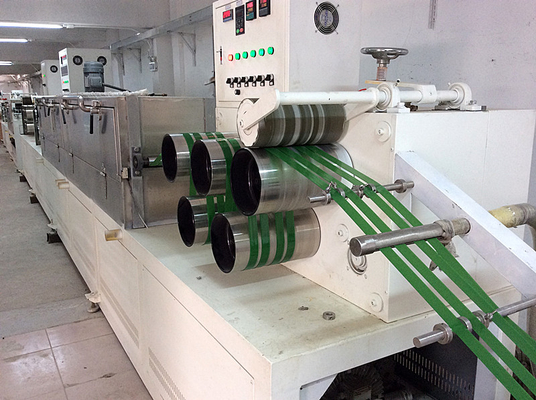

Water cooling tank system |

| 8 |

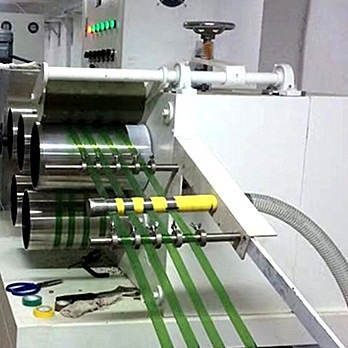

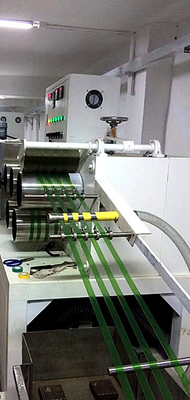

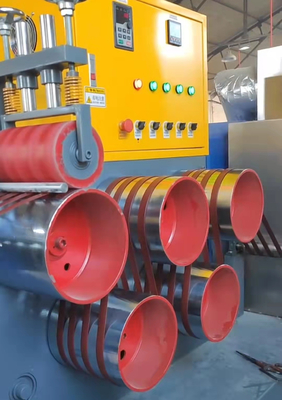

The first haul-off device |

| 9 |

Stretching oven |

| 10 |

The second haul-off device |

| 11 |

PLC electrical control system |

| 12 |

Embossing machine |

| 13 |

Forming oven |

| 14 |

Cooling system |

| 15 |

The third haul-off device |

| 16 |

Double disk winder |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews