Packaging machinery PET strapping production line PET plastic steel strapping equipment with PLC control system

Product Description:

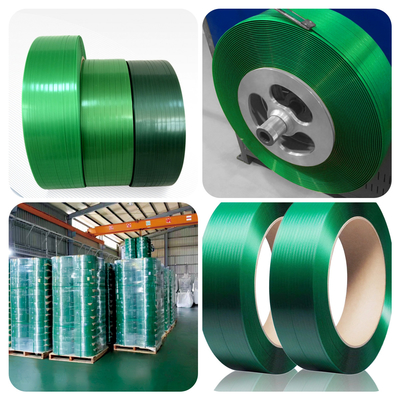

1. Good tensile strength----PET strapping tape production line has the tensile strength of steel tape, good ductility, good impact resistance, not easy to break, and ensures the safety of product transportation.

2. Small elongation----Although PET strapping tape is a kind of plastic, its elongation changes very little, and its elongation is only 1/6 of polypropylene. It can maintain tension and make the expansion and contraction amount no longer change after packaging.

3. Strong temperature resistance----Experiments have proved that the melting point of PET strapping tape is about 260℃, and it can be used for a long time at 120℃ without deformation, and has good stability.

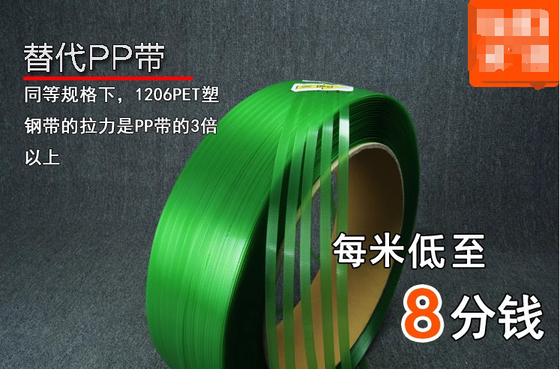

4. Good economic benefits-------The density of PET strapping tape is 1.30~1.38g/cm3, which is only 1/6 of the density of steel tape (7.8g/cm3), equivalent to the length of 6-ton steel tape, and the price per unit length is relatively low.

5. Environmental protection ------- steel straps will rust when exposed to the air, and rust is highly permeable to packaging. PET strapping is beautiful and rust-free, eliminating unnecessary worries. It can also be recycled.

6. Good flexibility - safe operation: PET strapping does not have the sharp edges of steel straps, will not scratch packaging, and will not hurt your hands. No special tools are required for cutting, and even if it is very tight, it will not hurt your hands when cutting.

7. High-quality products - -----PET strapping has different colors, bright luster, and excellent quality. It is the most ideal packaging product for high-end packaging

Features of PET strapping production line:

1. Good tensile strength----PET strapping production line has the tensile strength of steel strap, good ductility, good impact resistance, not easy to break, ensuring product transportation safety.

2. Small elongation----Although PET strapping is a kind of plastic, its elongation changes very little, and its elongation is only 1/6 of polypropylene. It can maintain tension and keep the expansion and contraction amount unchanged after packaging.

Technical Parameters:

| Product Name |

PET Strap Making Machine |

| Strap Material |

100% PET bottle flakes or crushed materials |

| Strap Core Material |

Paper/Plastic/Aluminum |

| Power Consumption |

2.2KW |

| Production Capacity |

420-600kgs/H |

| Strap Thickness |

0.4-1.2mm |

| Strap Color |

White/Black/Blue/Green Etc. |

| Strap Speed |

150-200m/min |

| Power Supply |

220V/380V |

| Memory Parameter |

SIMENS |

PET plastic steel belt production line features:

Extrusion process-----PET belt making machine uses a special screw for extruder, which is evenly extruded by heating and melting.

Cooling and solidification----The extruded PET belt embryo is then cooled and solidified using a cooling water tank or other refrigerator to ensure that the material maintains its shape and characteristics.

Stretching and orientation----PET belt making machines usually include stretching and orientation parts to improve the tensile strength, flexibility and overall performance of the PET belt. This process aligns the molecules in the PET material to enhance its mechanical properties.

After-sales service

Our PET plastic steel belt equipment provides comprehensive technical support and services. We have an experienced technical team that can quickly provide a variety of services, including:

Pre-sales:

1. Layout of PET plastic steel belt equipment.

2. Analysis of finished product manufacturing costs of PET plastic steel belt equipment.

3. Analysis of raw materials used in PET plastic steel belt equipment.

After-sales service:

1. Waterway diagram, circuit diagram, pipeline connection drawings, etc. of PET plastic steel belt equipment.

2. Installation, commissioning and training of PET plastic steel belt equipment.

3. Maintenance service of PET plastic steel belt equipment.

4. Regular maintenance and repair

5. Fault diagnosis

6. Software update and upgrade

7. Spare parts and accessories

8. Training and technical consultation

FAQ:

- Q1: What is the brand name of the PET Strap Making Machine?

- A1: The brand name of the PET Strap Making Machine is JIATUO CHINA.

- Q2: What is the model number of the PET Strap Making Machine?

- A2: The model number of the PET Strap Making Machine is JTPET.

- Q3: Where is the PET Strap Making Machine produced?

- A3: The PET Strap Making Machine is produced in China.

- Q4: Does the PET Strap Making Machine have any certifications?

- A4: Yes, the PET Strap Making Machine has IS CEO certification.

- Q5: What is the minimum order quantity of the PET Strap Making Machine?

- A5: The minimum order quantity of the PET Strap Making Machine is 1 SET.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews