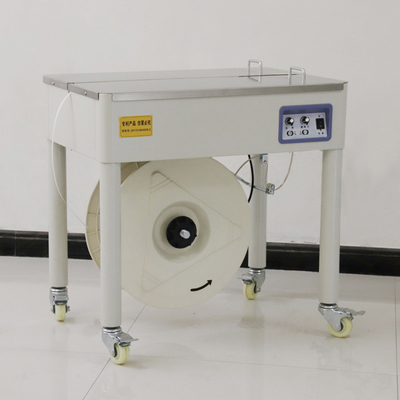

Upright Semi-Auto Polypropylene Banding Machine Strapping Packing Packaging Machine

DESCRIPTION OF STRAPPING PACKING MACHINE

Semi-automatic strapping machines typically include the following key components:

Frame---- A sturdy steel structure that provides stable support.

Reel----- Mounts and supports the rolled strapping tape.

Tape feed guide----- Guides the strapping tape into the machine.

Tape retraction and tightening mechanism------ The core component responsible for tightening the strapping tape.

Electric heat welder----- Heats and melts the strapping tape to create a bond.

Drive system----- Includes a motor and gears, providing power for retraction and tightening.

Control panel-------- Typically includes a power switch, tension adjustment knob, and heating time adjustment knob.

| Cycle Time |

2 sec./strap |

| Tension Range |

3~40kgs |

| Strap Width |

5,6,9,12,15.5mm adjustable |

| Sealing Method |

Heating element |

| Reel Inside Diameter |

200,230,280mm specified |

| Power Supply |

100/110/220/230/240V 50/60HZ, 1PH |

| Table Height |

750~830mm adjustable |

| Power Consumption |

0.4kw |

Machine Dimension

(L x W x H mm) |

L845 x W430 x H750 |

Machine Weight

(50%,100%,150%,200%) |

65kgs |

Features of the semi-automatic strapping machine for PET strap:

1. It has two motors. The strapping tension is controlled by electronic. The strapping tension is strong.

2. It's no need to adjust the machine if the thickness of the strap is different.

3. It's more power-saving. Its energy used is the half of other normal packing machine.

4. Its working noise is lower than normal about 50%.

5. All the main electronic components of our packing machine used are Siemens.

6.Convenient operators panel.

7.Externally controlled tension.

8.Integrated circuit control board.

How to use semi-automatic strapping machine:

1. Power switch: Turn ON to start the machine, and OFF to stop the machine.

2. Power indicator light (POWER): Turn on the power switch, the light is on.

3. Length adjustment for strap feeding (TIMER): Every one scale is about 500mm.For any adjustment that is required turn it in the clockwise direction. The length of the strap will then become longer.

4. Strap tension button (TENSION): Choose the tension degree of a strap according to the size of the package.

5. Manual feeding/Reset button (FEED/HOME): Press the FEED button to help feed the straps. The longer you press, the longer the strap will be. 6. If the machine is not at the home position, press the HOME button so that the machine will return to its home position.

7. Cooling time adjustment (COOL TIME): Depending on the strap and the different tensile strength, adjust the cooling time, for better adhesion effects.

8. Safety door switch: If the top cover is opened, the machine will stop running automatically. (Please turn off the main power switch before opening top cover.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews