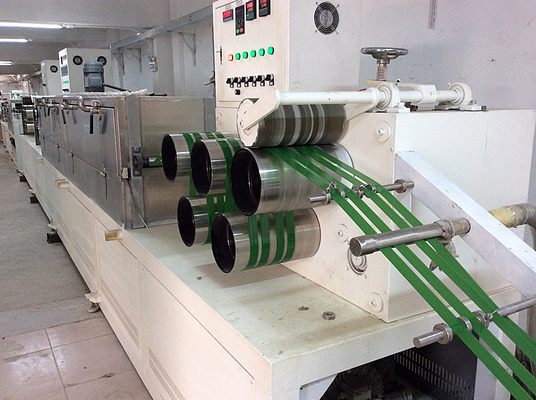

PET Polyerster Plastic Strap Production Line Band Packaging Belt Extruding Machine

PET PACKAGING BELT EXTRUDING MACHINE DESCRIPTION

1.Single screw or twin screw technique for option depending on the requirement.

2.100% recycled flakes can be used for production.

3. Even plasticization and stable extrusion with PC automatic control for the full line.

4. The fiflter of double columns with four working positions can get rid of impurity effective.

5. Single strap or double strap for option.

EXTRUSION PARAMETERS TABLE

| Model |

PET-2 |

PET-3 |

PET-4 |

PET-6 |

PET-8 |

| Raw materials |

100% Bottle flakes/crushed materials |

| Number of tapes |

2 |

3 |

4 |

6 |

8 |

| Width (mm) |

9-32 |

| Width (mm) |

0.4-1.2 |

| Maximum line speed(m/min) |

≧150 |

≧150 |

≧150 |

≧150 |

≧150 |

| PLC control system |

PLC |

PLC |

PLC |

PLC |

PLC |

| Screw Model |

90 |

100 |

125 |

150 |

180 |

| Reducer model |

200 |

250 |

280 |

315 |

350 |

| Dryer tank |

3000L |

4000L |

5000L |

6000L |

6000L |

| Dehumidifier |

1000 |

1000 |

2000 |

3000 |

3500 |

| Metering Pumps |

100CC |

100CC |

100CC |

100CC |

100CC |

| Screen Changer |

Single cylinder |

| Winding machine |

Automatic winding/ Semi-automatic winding |

| Production capacity /24 H |

5-6T |

7-8T |

10-12T |

12-15T |

18-20T |

PET strapping production line process flow

① Loading →② Mixing raw materials →③ Pre-drying raw materials →④ Vacuum dehumidification of raw materials →⑤ Melting and metering extrusion of raw materials →⑥ Cooling and forming of raw materials (with raw materials) →⑦ Preheating the oven →⑧ Primary stretching →⑨ Secondary stretching →⑩ Embossing →⑪ Oven tempering and shaping →⑫ Cooling →⑬ Finished product winding

Features of PET packing strap production line:

The features of line are as follows: screw with compression ratio especially for PP/PET, gradually changing diameter and deeper thread groove at the melting part; gearbox with hardened gears; die can be precisely adjusted to ensure stable production and smooth surface of straps; stainless steel cooling trough with four thermo treatment processes displaces the traditional one; haul off rollers with bigger size ensure the quality of products; new rolling technology overcomes the shortcomings of traditional rolling machine like high gradient and bending delection; laser embossing roller makes clear and even patterns.

PET packing strap is widely used, replaced for steel strap for packing application internationally, because of its good tensile strength, flexible, low prolongation rate, good performance of high temperature resistant, non-rustiness, and low use-cost, etc, it is used in steel, construction material, chemical fiber, paper making, tobacco, agriculture, election, etc.

FAQ

1. Q: How can I purchase your goods?

A: Please choose your perfect item and tell us your size, quantity and packing you want.

2. Q: How long is the lead time?

A: Normal order within 10-30 days after deposit.

3. Q: Do you offer sample?

A: Samples can be sent for your reference, but charge is required, after making formal order, the cost of samples will be cut from the total amount.

4.Q: What is the MOQ on your products?

A: Small quantity can be acceptable, depends on the stock.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews