PP strapping semi-automatic strapping machine multi-functional manual strapping tool

PRODUCT DESCRIPTION OF AUTOMATIC STRAPPING MACHINE

Semi-automatic strapping machines:

Specifically, the manual tasks required are:Apply the strapping tape around the box.Insert the front end of the tape into the machine.After strapping is complete, the manual tasks involve removing the box.Automatically, the machine performs the following tasks:Tighten the strapping belt.Fuse the ends of the tape together using hot melt.Cut the strapping belt

| Cycle Time |

2 sec./strap |

| Tension Range |

3~40kgs |

| Strap Width |

5,6,9,12,15.5mm adjustable |

| Sealing Method |

Heating element |

| Reel Inside Diameter |

200,230,280mm specified |

| Power Supply |

100/110/220/230/240V 50/60HZ, 1PH |

| Table Height |

750~830mm adjustable |

| Power Consumption |

0.4kw |

Machine Dimension

(L x W x H mm) |

L845 x W430 x H750 |

Machine Weight

(50%,100%,150%,200%) |

65kgs |

Features of the semi-automatic strapping machine for PET strap:

High engineering standard and simple design

Easy operation, simple maintenance

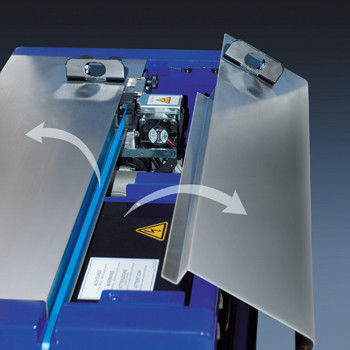

Hinged stainless steel top plate

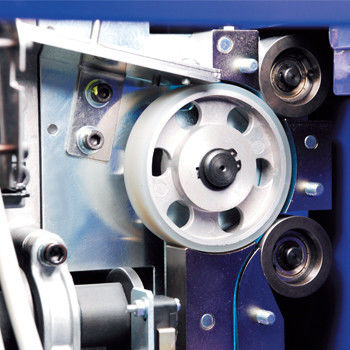

Mechanical outside tension control

Rigid castors with brake

Energy efficient, motor only runs as needed

Reliable P.C. Board control

Affordable for every budget

Offer maximum total value among competing brands

Proven quality

Core Working Principle

The workflow of a semi-automatic strapping machine can be summarized as follows:

1. Threading----- The operator threads the strapping tape around the box and feeds the front end of the tape into the machine's inlet.

2. Sensor Start------- The machine automatically starts (or the operator presses a button) upon sensing the insertion of the strapping tape.

3. Tapering and Tightening------ The machine's motor drives the take-up reel, pulling the strapping tape back to securely wrap the package. The tension can be adjusted as needed.

4. Hot Melt Bonding----- When the tension reaches the preset value, the machine's hot melt head moves to the overlapping portion of the strapping tape (usually the top and bottom layers), heating and melting it.

5. Laminating and Cutting-----The hot melt head applies pressure while heating, firmly pressing the two ends of the melted tape together to form a secure joint. The cutter then quickly removes any excess tape.

6. Reset------ After bonding and cutting, the hot melt head resets, returning the machine to standby mode, ready for the next operation.

Suitable for PP packing straps:

FAQ:

Q: Can the size of the strapping machine be customized?

Yes, it can be customized according to requirements, but the delivery time will be longer.

Q: Does the semi-automatic strapping machine have after-sales service?

A: We are a manufacturing plant with our own engineering and after-sales teams.

Q: What is the voltage of the semi-automatic strapping machine?

A: Single phase: 220V/60HZ.

Q: What are the packaging methods for the semi-automatic strapping machine?

A: The semi-automatic strapping machine uses export wooden crates or standard export cartons for strapping.

Q: What packaging materials are suitable for the semi-automatic strapping machine?

A: PP strapping, width: 5-15mm (optional).

Q: What are the payment methods for the semi-automatic strapping machine?

A: We support: Wire Transfer (TT), negotiable.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews