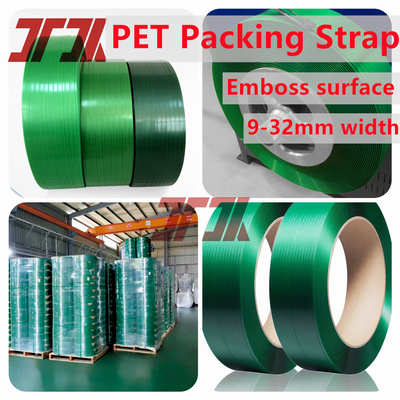

Plastic Machinery PP PET Strapping Equipment PET Plastic Steel Strapping Production Line 100-600KG/H Extrusion Capacity

PRODUCT DESCRIPTION

PET plastic steel belt production line features:

Extrusion process-----PET belt making machine uses a special screw for extruder, which is evenly extruded by heating and melting.

Cooling and solidification----The extruded PET belt embryo is then cooled and solidified using a cooling water tank or other refrigerator to ensure that the material maintains its shape and characteristics.

Stretching and orientation----PET belt making machines usually include stretching and orientation parts to improve the tensile strength, flexibility and overall performance of the PET belt. This process aligns the molecules in the PET material to enhance its mechanical properties.

EXTRUSION PARAMETERS TABLE

| Name |

PET packing strap making machine |

| Applicable raw materials |

100% bottle flakes or crushed materials |

| Number of screws |

Single Screw |

| Screw model |

150 |

| Number of extruded belts |

6 |

| Width range |

9-32mm |

| Thickness range |

0.4-1.2mm |

| Production capacity |

600-650kg/h |

| Metering Pumps |

150CC |

Features of PET packing strap production line:

PET strapping and steel strap comparison:

1 Appearance: The steel strip will rust due to exposure to moisture in the air. The strong rust permeability will easily contaminate the packaged object, and the PET strap will not rust, the color will be bright, and it is environmentally friendly. No need for steel buckle combination, no indentation, scratching,

Economic Benefit: The length of 1 ton PET strapping is equivalent to 6 tons of steel belt. The unit price per meter is lower than steel belt, which can reduce the cost for you.

2 Safety: PET plastic belt has no sharp edge of steel strip, will not scratch the package, and will not hurt the hand. Even if the binding is tight, it won't hurt when you cut it.

3 Packaging performance: The coating tightness after packaging is good. After long-distance transportation of the package, there will be expansion and contraction, and the PET tape can maintain a good tension. PET steel strip has good ductility, good impact resistance, and is not easy to break, which ensures the safe transportation of your products.

4 Economic Benefits: The density of PET plastic strip is only 1/6 of the density of steel strip, and the price per unit length is relatively low.

DETAILS ABOUT PET STRAP MAKING MACHINE

1. Components of pp pet packing belt machinery:

PET Strap Production Line consists of dehumidifying and crystallizing system, extruder, screen changer, mold, oven, haul-off, and winder, etc.

2. Production Process of PET Machinery

Material→ Dehumidifying and Crystallizing → Extruding → Mold → Cooling → Haul-off →Oven Heating →Pre-heating → Drawing and Stretching →Drawing and Stretching → Embossing →Hot Forming → Drawing → Winding

3. Application

With 100% bottle flakes recycled material, to produce various specifications of PET strap. It has been widely used in steel, chemical industry, aluminum, paper making, brick kiln, tobacco, electronics and textile and timber industries.

FQA:

Q: What is the voltage of the PET plastic steel belt equipment?

A: 380V/50HZ, three-phase (customization supported)

Q: What is the extrusion capacity of the PET plastic steel belt equipment?

A: Different models have different extrusion capacities, with capacities ranging from 150-600KG/H

Q: What is the producible width of the PET plastic steel belt equipment?

A: 9-32mm

Q: Can the PET plastic steel belt equipment be customized?

A: Customization supported

Q: Where does the PET plastic steel belt equipment come from?

A: China.

Q: What are the certifications for the PET plastic steel belt equipment?

A: ISO CEO certification.

Q: What is the minimum order quantity for the PET plastic steel belt equipment?

A: 1 set

Q: What is the weight of the PET plastic steel belt equipment?

20T, 40GP container * 3PCS

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews