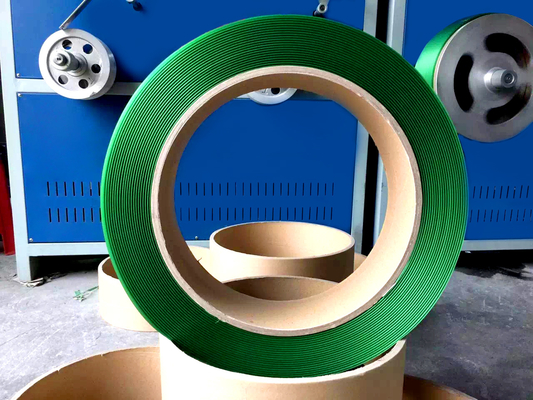

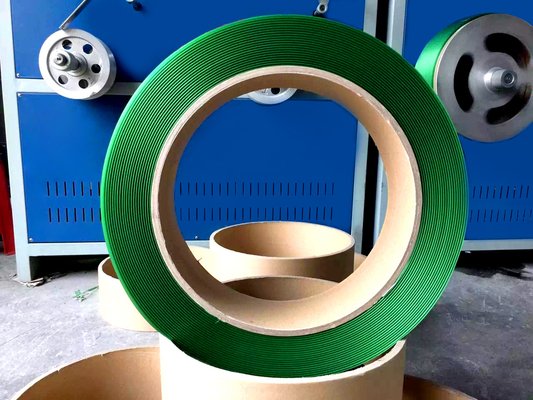

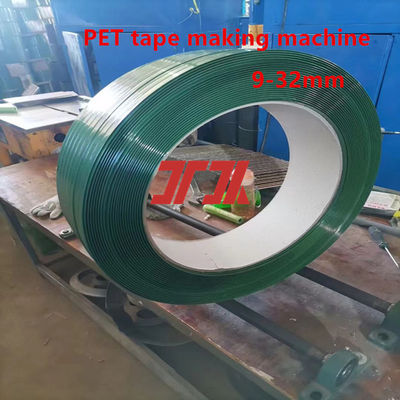

Polyester PET Strap Making Machine Belt Package Production Line Siemens Motor

PRODUCT DESCRIPTION

PET strap, also known as plastic steel band, which is used in place of steel on the world of a new environmentally friendly packaging materials, the development of new materials in recent years the cost of success and a substantial decline, have been widely used in the steel industry, chemical fiber industry, aluminum ingots, paper, brick kiln industry, screw industry, tobacco industry, electronics, textiles and wood, etc.; It is replaced by a new high-strength steel strapping, is the world’s most widely used for steel products with high strength.

PET Strap Production Line Machine List

| NO. |

Item |

Specification |

| 1 |

Power |

According to customer's factory voltage |

| 2 |

Material |

PET raw material or 100% PET bottle flakes recycled |

| 3 |

Capacity |

PETJT90:200kg/h

PETJT100:250kg/h

PETJT125:350kg/h

|

| 4 |

Product size |

Width:9-32mm

Thickness:0.6-12mm

|

| 6 |

Mid-height of extruder |

7000mm |

| 7 |

Installation power |

PETJT90:200KW

PETJT100:250KW

PETJT125:300KW

|

| 8 |

Humidity |

<85% |

| 9 |

Temperature |

0-40 degree |

| 10 |

Cooling tower capacity |

30T/H or 50T/H |

| 11 |

Installation Dimensions |

PETJT90:45*2.0*7.0M

PETJT100:45*2.0*7.0M

PETJT125:60*3.0*8.0M

|

| 12 |

Product color |

Green/Black/Pink/Yellow |

| 13 |

Factory dimension |

35m*(3~6)m*(4~6)m

45m*(3~6)m*(4~6)m

If your factory not big enough,please contact with us,our engineer can according to your size to design

|

Features of PET packing strap production line:

PET packing belt finished product features: made of POLYESTER (PET) material, commonly known as plastic steel belt, is made of polyethylene terephthalate as the main raw material, it is currently used as a substitute for steel belt in the world. A new type of environmentally-friendly packaging material has been widely used in the steel industry, chemical fiber industry, aluminum ingot industry, paper industry, brick kiln industry, screw industry, tobacco industry, after the development of new materials and the significant cost reduction in recent years. Electronics, textiles and wood.

1 Tensile: PET plastic strip is a kind of packaging material with good tensile strength and excellent welding performance.

2 The elongation is small: the elongation is only one-sixth of that of the polypropylene (PP) belt, and the tension can be maintained for a long time.

3 strong temperature resistance: melting point of 260 degrees, superior weather resistance, between -50 ° C -120 ° C, maintaining good stability.

Core Components of PET Plastic Steel Strip Equipment:

1. Five-Roller Stretching System

Stretching Unit: Equipped with 3-5 sets of traction rollers, utilising silicone or chrome-plated rollers to prevent strip scratching; adjustable stretching speed range of 5-20m/min accommodates production requirements for plastic steel strips of varying thicknesses (0.4-1.2mm).

2. Five-Roller Forming System

Temperature Control System: Utilises a PLC control system with touchscreen operation, achieving ±1℃ precision across the entire line. Real-time temperature curves for each section are displayed, with fault alarm functionality (e.g., temperature anomalies, motor overload) enabling prompt operator intervention.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews