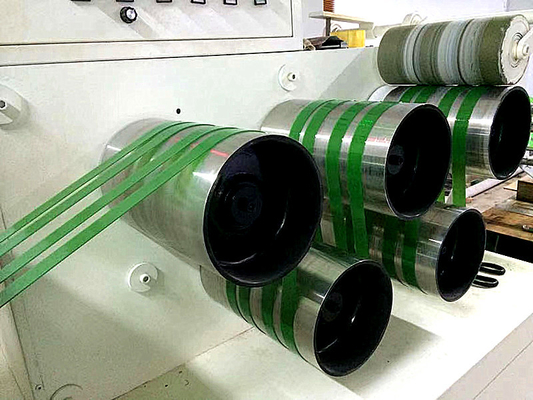

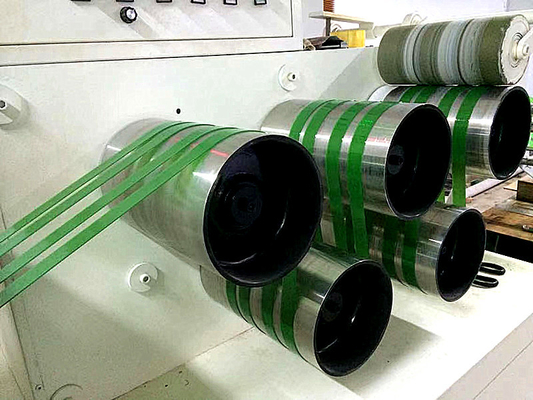

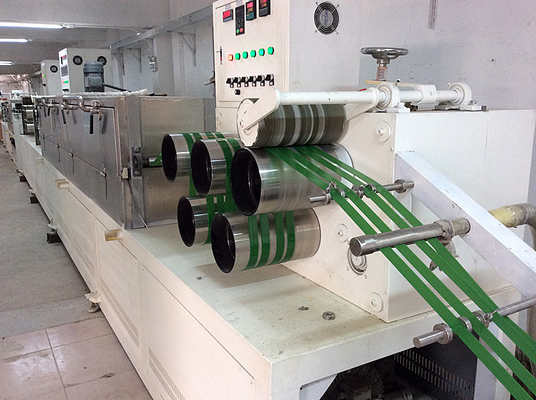

High Speed PET Strap Production Line Recycled PET Extruder Strap Band Making Machine

PRODUCT DESCRIPTION

Descripition:

This machine is mainly used to make PET strap ,PP packing strap.

Our machines adopts the PLC control to realsize the whole line auotmatic production.

Using the melting pump and pressure sensor ensure the production stable and strap quality control.

The raw material can be 100% recycled pet flakes from the waste pet bottles,or virgin material or mixed with each other.

PET Strap Production Line Machine List

| NO. |

Item |

Specification |

| 1 |

Power |

According to customer's factory voltage |

| 2 |

Material |

PET raw material or 100% PET bottle flakes recycled |

| 3 |

Capacity |

PETJT90:200kg/h

PETJT100:250kg/h

PETJT125:350kg/h

|

| 4 |

Product size |

Width:9-32mm

Thickness:0.6-12mm

|

| 6 |

Mid-height of extruder |

7000mm |

| 7 |

Installation power |

PETJT90:200KW

PETJT100:250KW

PETJT125:300KW

|

| 8 |

Humidity |

<85% |

| 9 |

Temperature |

0-40 degree |

| 10 |

Cooling tower capacity |

30T/H or 50T/H |

| 11 |

Installation Dimensions |

PETJT90:45*2.0*7.0M

PETJT100:45*2.0*7.0M

PETJT125:60*3.0*8.0M

|

| 12 |

Product color |

Green/Black/Pink/Yellow |

| 13 |

Factory dimension |

35m*(3~6)m*(4~6)m

45m*(3~6)m*(4~6)m

If your factory not big enough,please contact with us,our engineer can according to your size to design

|

Advantages of PET strap

- Use 100% Recycled PET/PP Flakes to reduce the cost.

- Good dehumidifer drying system(Crystallization system optional ) to ensure the material equal dryer to produce high quality strapping.

- Special design hot forming tensile tank to make good forming ,equal width,straight strap.

Features of PET packing strap production line:

Features: This production line uses PET waste mineral water, Sprite, Coke and other bottle flakes as raw materials to produce packing belts, with low cost and high efficiency.

The computer control system is used for real-time control of melt temperature, pressure, extrusion speed, torque, traction, etc. to ensure product quality. Equipment composition: Special equipment Three stretching machines, ovens, molds, traction machines, control boxes, winders, etc. General equipment Feeder, extruder, mold temperature machine, chiller, dryer, air compressor, etc.

Features: ·PET belt, also known as plastic-steel belt, is a new type of strapping belt that is popular in the world to replace steel belt. It is widely used in steel, aluminum, chemical fiber, cotton spinning, tobacco, paper, metal can making and other industries.

·Strong tensile strength: It has both the tensile strength like a steel belt and the ductility that can resist impact, which can ensure the safety of your product transportation.

·Small elongation: The elongation is only one-sixth of that of polypropylene (PP) tape, which can maintain tension for a long time.

· Strong temperature resistance: the melting point is 260 degrees, and it will not deform when used below 120 degrees. ·Good flexibility: no sharp edges of steel belts, safe operation, neither hurting hands nor damaging the bundled objects.

·Beautiful appearance and no rust: There is no risk of rusting the steel belt to contaminate the bundled objects, and the color is bright and can be seen.

·Good economic benefits: The length of 1 ton of plastic steel belt is equivalent to 6 tons of steel belt, and the unit price per meter is lower than that of steel belt, which can reduce the cost for you.

FAQ

Q1:Are you a trading company or a manufactory?

A1:We are a manufactory,can give u best service.

Q2:What's your guarantee or the warranty of the quality if we buy your machines?

A2:We offer you high quality machines with 1 years guarantee . we will give u spare part free in 1 years.

Q3:When can I get my machine after I paid?

A3:We will deliver the machines on time as the date we agreed both side.

Q4:How can I install my machine when it arrives?

A4:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

Q5:How about the spare parts?

A5:After we deal down all the things , we will offer you a spare parts list for your reference.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews