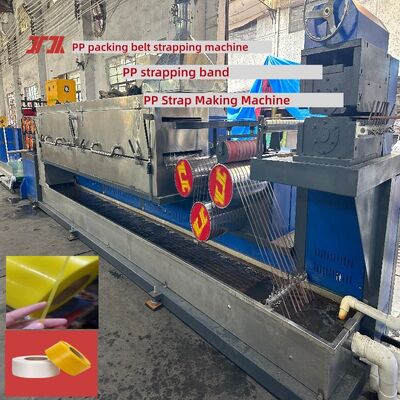

PP packing strap making machine 5-19mm PP packaging belt production line Automatic screen changing device

DESCRIOTION OF PP PACKING STRAP MAKING MACHINE:

pp packing belt making machine/pp packing strap making machine

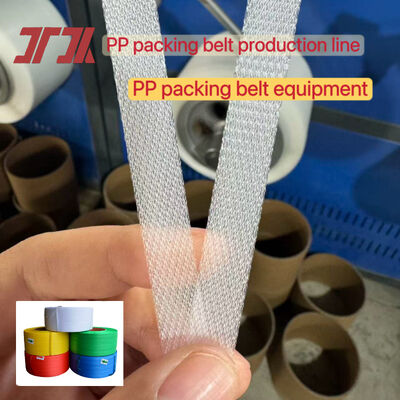

pp packing belt making machine is a mechanical equipment used to produce polypropylene (PP) plastic belts, which are widely used in packaging, printing, textile, ceramics, printing, logistics, home appliances and other industries.

PARAMETER TABLE

| Model |

PP-2 |

PP-4 |

PP-6 |

PP-8 |

PP-10 |

PP-12 |

| Raw material |

PP polypropylene new material/recycled material |

| Number of tapes |

2 |

4 |

6 |

8 |

10 |

12 |

| Width(mm) |

5-19 |

5-19 |

5-19 |

5-19 |

5-19 |

5-19 |

| Thickness(mm) |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

| Line speed(m/min) |

≧260-300 |

| PLC control system |

PLC |

PLC |

PLC |

PLC |

PLC |

PLC |

| Screw Model |

90 |

110 |

125 |

135 |

135 |

135 |

| Reducer model |

200 |

220 |

250 |

280 |

280 |

280 |

| Winding machine |

Automatic winding machine /Semi-automatic winding machine |

| Screen Changer |

Automatic/Manua |

| Production capacity 24H |

2.5-3T |

6-7T |

8-9T |

10-11T |

12-13T |

13--14T |

The main components of PP strapping equipment:

Feeder---- transfer PP raw materials into the machine.

Extruder----heat and melt the PP raw materials and extrude them into shape.

Molding mold---- make the molten PP belt embryo pass through the mold to form a strip.

Cooling water tank----cool the extruded PP belt embryo to ensure its shaping.

Tractor----pull out the cooled strapping tape to maintain a stable production speed.

Oven---- heat the strapping tape to improve its strength and toughness.

Embossing machine---- emboss the surface of the strapping tape to increase friction and prevent slipping.

Shaping oven----heat again, shape, and make the PP belt more standardized.

Reeler---- reel the strapping tape into rolls for easy storage and transportation.

ABOUT AFTER-SALES

We provide comprehensive technical support and service for our PP Strap Making Machine. Our team of experienced technicians can provide a variety of services, including:

Pre-sales:

1.Layout plan of pp packing strap making machine.

2.Analysis of the cost of Ppp packing strap making machine.

3.Raw materials that can be used for pp packing strap making machine.

After-sales service:

1.Water and electricity circuits of pp packing strap making machine, circuit drawings, etc.

2.Installation, commissioning and training of pp packing strap making machine.

3.Maintenance service of pp packing strap making machine.

4.Regular maintenance and repair

5.Troubleshooting and diagnosis

6.Software updates and upgrades

7.Spare parts and accessories

8.Training and technical advice

FAQ:

Q: What are the specifications that the pp packing strap making machine can produce?

A: Width: 5-19mm, thickness: 0.3-1.2mm.

Q: What's the price of this machine please?

A: We have different extrusion capacities and different models, and the corresponding prices are also different.

Q:What is the transaction method of pp packing strap making machine?

EXW ,FOB,CIF

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews