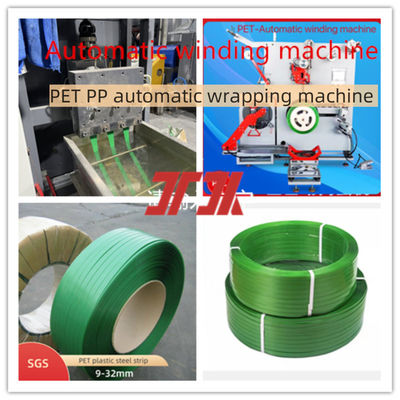

Automatic Winding Machine PP PET Strap Winding Machine Servo Winding Machine

PRODUCT DESCRIPTION OF AUTOMATIC WINDING MACHINE:

Automatic Winding Machine /PP PET Strap Winding Machine/ Servo Winding Machine

Main functions of the automatic winding machine:

1) The automatic winding machine uses a servo motor for wire arrangement and is suitable for winding PP/PET strapping (PP strapping width: 5-19mm, PET width: 9-32mm). The appropriate strap width is selected via the PLC touchscreen for winding. The entire process does not require manual replacement of gears or belt grooves.

2) After the entire roll of strapping is wound, the machine automatically stops, automatically replaces the paper core, automatically cuts the strapping and clamps the strap end, and automatically changes rolls for the next winding operation. The entire process is completed automatically.

3) The winding reciprocating shaft is controlled using the torque mode of the servo motor. The winding torque can be set and adjusted via the PLC touchscreen, allowing different weights or widths of strapping to be wound with appropriate torque, minimizing bending and deformation of the strapping after winding.

PARAMETER TABLE

| Name |

Automatic Winding Machine |

| Tape width |

5-19mm |

| Thickness |

0.4-1.2mm |

| Control mode |

servo motor |

| Pressure |

4-7kgf |

| PLC control |

YES |

| Paper tube |

Ø200*180/190mm |

| Max weight |

10kg/roll |

| power single-phase |

220V |

| Weight |

650KG |

| Overall dimension |

(L)1900mm*(W)1850mm*(H) 1800mm |

Efficient Automation

①Fully Automatic Operation---------- Simply set the parameters, and the machine automatically completes the wrapping, lifting, and strapping processes, significantly reducing manual intervention.

②Fast Packaging----------- Adjustable wrapping speed (typical line speed: 200-300 m/min) makes it suitable for large-scale continuous operations, increasing efficiency 3-5 times compared to manual wrapping.

③One-Button Start--------- Simple operation, reducing worker skill requirements.

SERVICE:

1. Shelf life: 12 months

2. Consumable parts: spare parts are available

3. Support 24-hour online service.

4. Free system upgrade service.

5. Remote detection service.

FQA:

Q: Where is the automatic winding machine made?

A: China

Q: What is the voltage of the automatic winding machine:

A: 220V

Q: What mode is the automatic winding machine controlled by?

A: Servo motor control

Q: Can the automatic winding machine be purchased separately?

A: Yes

Q: Does the automatic winding machine require manual operation?

A: No, the entire process is controlled by PLC computerization.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews