PP strapping machine 5-19mm PP strapping production line PP strapping manufacturing machine

PRODUCT DESCRITION OF PP STRAP MAKING MACHINE:

PP Strapping Band Extrusion Line/PP Strap Making Machine

The PP Strapping Band Extrusion Line is a PP Band Extrusion Production Line used for producing high-end PP strapping bands. It is equipped with a PLC Control System, providing a low failure rate and first-class technology. The line is characterized by beautiful and generous design and its operation mode is PLC Computer Touch Screen, making it easier to operate.

| Model |

PP-2 |

PP-4 |

PP-6 |

PP-8 |

PP-10 |

PP-12 |

| Raw material |

PP polypropylene new material/recycled material |

| Number of tapes |

2 |

4 |

6 |

8 |

10 |

12 |

| Width(mm) |

5-19 |

5-19 |

5-19 |

5-19 |

5-19 |

5-19 |

| Thickness(mm) |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

| Line speed(m/min) |

≧260-300 |

| PLC control system |

PLC |

PLC |

PLC |

PLC |

PLC |

PLC |

| Screw Model |

90 |

110 |

125 |

135 |

135 |

135 |

| Reducer model |

200 |

220 |

250 |

280 |

280 |

280 |

| Winding machine |

Automatic winding machine /Semi-automatic winding machine |

| Screen Changer |

Automatic/Manua |

| Production capacity 24H |

2.5-3T |

6-7T |

8-9T |

10-11T |

12-13T |

13--14T |

The main components of PP strapping equipment:

Feeder---- transfer PP raw materials into the machine.

Extruder----heat and melt the PP raw materials and extrude them into shape.

Molding mold---- make the molten PP belt embryo pass through the mold to form a strip.

Cooling water tank----cool the extruded PP belt embryo to ensure its shaping.

Tractor----pull out the cooled strapping tape to maintain a stable production speed.

Oven---- heat the strapping tape to improve its strength and toughness.

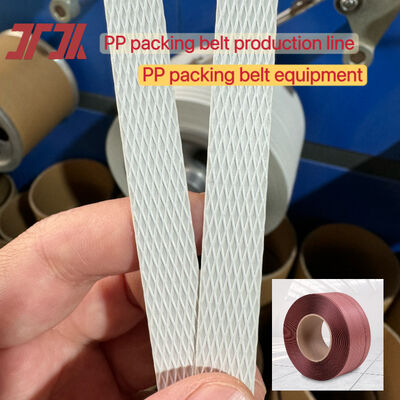

Embossing machine---- emboss the surface of the strapping tape to increase friction and prevent slipping.

Shaping oven----heat again, shape, and make the PP belt more standardized.

Reeler---- reel the strapping tape into rolls for easy storage and transportation.

Support and Services of PP packing belt production equipment:

Technical Support and Service for PP Strap Band Extrusion Line

We offer a wide range of technical support and services for our PP Strap Band Extrusion Line products, including:

- Installation and commissioning of the extrusion line.

- Operational and maintenance training.

- Consultation and advice.

- Technical support.

- Spare parts supply.

- Regular maintenance.

- On-site repair and maintenance.

FAQ:

Q: What are the specifications that the PP strapping production line can produce?

A: Width: 5-19mm, thickness: 0.3-1.2mm.

Q: What's the price of this machine please?

A: We have different extrusion capacities and different models, and the corresponding prices are also different.

Q:Can the length of the PP strapping production line be customized?

A: YES

Q:What is the transaction method of PP strapping production line?

EXW ,FOB,CIF

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews