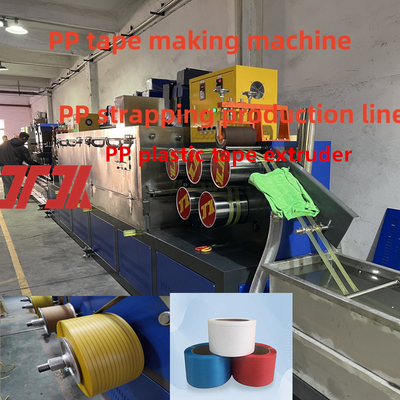

2-12 strips PP strapping band production line pp strapping band making machine automatic PP strapping band

Product Description of pp strapping band making machine:

pp strapping band making machine

pp strapping band making machine can be customized according to customer requirements and can extrude 2-12 PP straps at the same time.

WORKING PROCESS

Raw material preparation----Add PP granules into the extruder hopper.

Extrusion molding----PP granules are melted in the extruder and extruded through the mold.

Cooling and shaping----The extruded strapping tape enters the cooling water tank for cooling and shaping.

Traction and stretching---- The traction machine pulls the strapping tape, and the stretching machine performs stretching treatment.

Embossed treatment---- The embossing machine embosses the surface of the strapping tape.

Shaping oven---- Heat and shape the PP tape again to achieve consistent specifications.

Reeling and packaging----The reeling machine winds the strapping tape into a roll and puts it into storage after packaging.

Raw materials------

100% PP polypropylene new material or recycled material

EXTRUSION PARAMETERS TABLE

|

Model

|

PP-2

|

PP-4

|

PP-6

|

PP-8

|

PP-10

|

PP-12

|

|

Raw material

|

PP polypropylene new material/recycled material

|

|

Number of tapes

|

2

|

4

|

6

|

8

|

10

|

12

|

|

Width(mm)

|

5-19

|

5-19

|

5-19

|

5-19

|

5-19

|

5-19

|

|

Thickness(mm)

|

0.4-1.2

|

0.4-1.2

|

0.4-1.2

|

0.4-1.2

|

0.4-1.2

|

0.4-1.2

|

|

Line speed(m/min)

|

≧260-300

|

|

PLC control system

|

PLC

|

PLC

|

PLC

|

PLC

|

PLC

|

PLC

|

|

Screw Model

|

90

|

110

|

125

|

135

|

135

|

135

|

|

Reducer model

|

200

|

220

|

250

|

280

|

280

|

280

|

|

Winding machine

|

Automatic winding machine /Semi-automatic winding machine

|

|

Screen Changer

|

Automatic/Manua

|

|

Production capacity 24H

|

2.5-3T

|

6-7T

|

8-9T

|

10-11T

|

12-13T

|

13--14T

|

About auxiliary feeding system:

The PP strapping equipment is equipped with ---- 3 sets of auxiliary feeders,

Can add dyeing masterbatch------- change the color of PP strap

Can add filling masterbatch----- reduce the cost of PP strap by more than 30%

Can add defoaming agent-------- eliminate the moisture of PP raw materials

Services :

Technical Support and Service for pp strapping band making machine

We offer a wide range of technical support and services for our pp strapping band making machine products, including:

- Installation and commissioning of the extrusion line.

- Operational and maintenance training.

- Consultation and advice.

- Technical support.

- Spare parts supply.

- Regular maintenance.

- On-site repair and maintenance.

Packing and Shipping of pp strapping band making machine:

Packaging and Shipping for pp strapping band making machine:

- Product will be packaged in standard export cartons.

- The weight of each carton is less than 20KG.

- Transport methods include air, sea, express and railway.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews