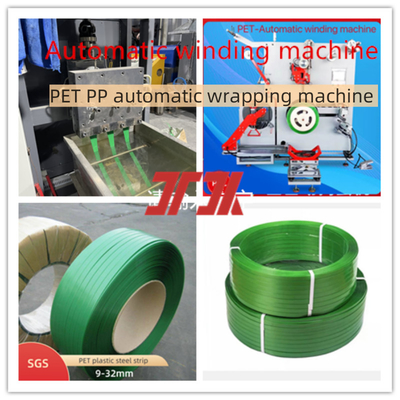

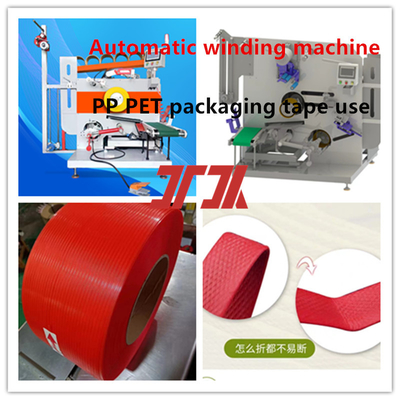

PP PET strapping automatic winding machine Servo winding machine PLC winding machine

Product Description of Automatic strapping machine:

The main functions of the automatic winder:

- The automatic winder uses a servo motor to arrange the wires, which is suitable for winding PP strapping band with a width of 5-19mm. The corresponding bandwidth is selected through the PLC touch screen for winding and winding. The whole process does not require manual replacement of the transmission gear and belt slot.

- After the whole roll of strapping tape is wound, the machine automatically stops, automatically replaces the paper tube, automatically cuts the strapping tape, fixes the strapping tape head with a clip, and automatically changes the roll for winding. The whole process is completed automatically.

- The rewinding axis uses the torque mode control of the servo motor. The torque during winding can be set and debugged through the PLC touch screen, so that strapping tapes of different weights or widths can be wound with appropriate torque, and the bending deformation of the strapping tape after winding can be minimized.

Line speed: 200-300 m/min

| Name |

PP PET Automatic Winding Machine |

| Tape width |

5-19mm |

| Thickness |

0.6-1.2mm |

| Control mode |

servo motor |

| Pressure |

4-7kgf |

| PLC control |

YES |

| Paper tube |

Ø200*190mm |

| Max weight |

20-350kg/roll |

| power single-phase |

220V |

| Weight |

700KG |

| Overall dimension |

(L)1400mm*(W)1200mm*(H) 1850mm |

Features of Automatic strapping machine:

Automatic operation----Automatic winding, automatic tape cutting, automatic roll changing, with simple settings, the equipment can automatically complete packaging, reducing manual intervention.

Intelligent control----equipped with PLC and touch screen, easy to operate, adjustable parameters, one-button operation.

High efficiency and energy saving----fast speed, 200-300 m/min, improve efficiency.

Energy-saving design----using energy-saving motors and frequency conversion technology to reduce energy consumption.

Shipping Packaging:

1.This PP PET automatic winding machine will pass strict inspection before leaving the factory, and field winding test.

2. This PP PET automatic winding machine will be packaged with PE soft film before leaving the factory, and then put into the wooden box for fixed packaging to ensure safe delivery.

3. This PP PET automatic winding machine will be delivered safely by sea transportation.

Services:

After-sales service:

The automatic winding machine provides comprehensive technical support and services. Our experienced team of technicians can provide a variety of services, including:

Pre-sales:

1. Layout diagram.

2. Labor cost analysis.

After-sales service:

1. Water and electricity lines, circuit diagrams, etc. of the automatic winding machine.

2. Installation, commissioning and training of the automatic winding machine.

3. Maintenance service of the P automatic winding machine.

4. Regular maintenance and repair

4. Fault diagnosis

6. Software update and upgrade

7. Spare parts and accessories

8. Training and technical consultation

FAQ:

- Q1: What is the brand name of the Strapping Band Winding Machine?

- A1: The brand name of the Strapping Band Winding Machine is Automatic PP packing and winding machine.

- Q2: What is the model number of the Strapping Band Winding Machine?

- A2: The model number of the Strapping Band Winding Machine is JTPP/PET.

- Q3: What is the place of origin of the Strapping Band Winding Machine?

- A3: The place of origin of the Strapping Band Winding Machine is CHINA.

- Q4: What is the purpose of the Strapping Band Winding Machine?

- A4: The Strapping Band Winding Machine is used to automatically wind PP strapping bands.

- Q5: Does the Strapping Band Winding Machine have any special features?

- A5: Yes, the Strapping Band Winding Machine can automatically count the number of winding layers, and it is equipped with a touch screen for easy operation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews