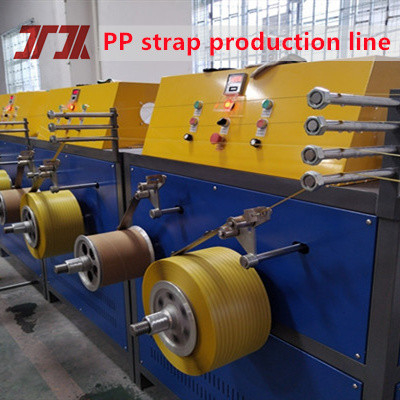

Manufacturer PP Packaging Belt Production Line For 5-19mm Width Customized Good Flexible And Tension

Product Description of PP strap making machine

PP strap production line is used to produce mechanical or manual bands with 100% PP recycled granules as materials, if raw materials, it will be better. This kind of band is widely used in the packing of kinds of fields such as mines, general merchandise, weaving, electrical equipment, apparatus, architecture, medicine, etc.

Technical Parameters of PP band extrusion line

| Speed |

Adjustable |

| Warranty |

1 Year |

| Thermostat |

Taiwan Fotek |

| Strap Width |

5-19mm |

| Extruder Power |

22KW |

| Colors |

Can Be Customized |

| Material |

PP Polypropylene New Material/recycled Material |

| Switches |

Schneider |

| Overall dimensions |

L36*W2.0*H4.0M |

| Control System |

PLC Touch Screen Control |

Advantages of Our PP Strapping Machine

1. High-Efficiency Multi-Line Production

Specifically engineered for PP strap manufacturing with flexible output options

Capable of simultaneous production of 2-12 straps (2,4,6,8,10,12 lines available)

Energy-saving design reduces power consumption by 20-30% compared to conventional machines

2. Durable Water Tank System

Features premium stainless steel forming and calibration water tanks

Corrosion-resistant construction ensures extended service life

3. Intelligent PLC Control System

User-friendly touchscreen interface with multi-language support

Parameter memory function enables quick setup for repeat production runs

Maintains optimal component performance for consistent output quality

Ensures stable operation throughout the entire production line

Application of PP strapping

1. Lightweight: Reduces shipping costs compared to metal strapping.

2. High Tensile Strength: Can withstand heavy loads (350-650kg as per your specification).

3. Resistance to Moisture: Ideal for humid or wet environments.

4. UV Resistance: Suitable for outdoor use.

5. Eco-Friendly: Can be made from recycled materials and is recyclable.

FAQ

1. What is a PP Production Line?

A PP Production Line is a manufacturing system designed to produce polypropylene (PP) products, such as PP straps, bands, sheets, or films. It typically includes extrusion, cooling, stretching, annealing, and winding processes to create high-quality PP materials.

2. What is the production speed of a PP Production Line?

The speed is adjustable and depends on the machine's design. Typical speeds range from 200 to 260 meters per minute, depending on the product type and thickness.

3. What is the tensile strength of PP straps produced by this line?

PP straps produced by a standard PP Production Line typically have a tensile strength ranging from 350 to 950 kg, making them suitable for heavy-duty applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews