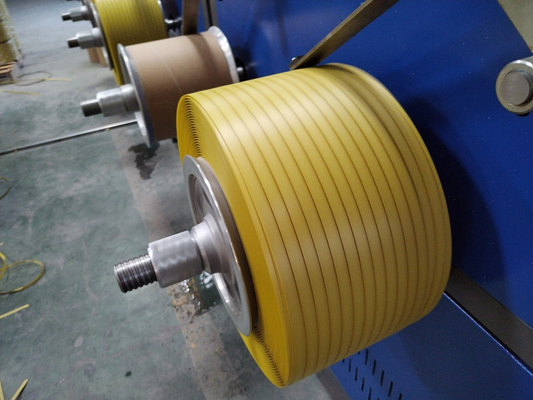

PP belt extrusion line, PP bundling machine production line, equipped with PLC touch screen, 37KW Siemens motor

Product Description of pp strapping band making machine:

There are the following criteria for judging the quality of PP baler belt:

1. The baler belt should have good toughness, fold the PP baler belt repeatedly, and it is easy to break if the toughness is not good. The pattern problem, the pattern must be beautiful, do not appear pressure bias.

2, PP baler belt is generally white (other colors should be bright) quality is better, because these are not easy to mix old materials.

3, the baler belt should have gloss, such a baler belt is generally produced by the whole material. Tensile stability. If the baler is mixed with powder, the gloss will be greatly reduced.

4, the width of the baler belt, the width error is generally plus or minus 0.5mm. In the production of such a baler belt, the feeding is uniform, and the quality will be relatively uniform, and there will be no good or bad situation.

5, some baler belt outside is a new material, the middle of the filling material (very poor), as long as cut to see the section can see the black heart inside is poor quality.

6.Baler belt color problem, baler belt grade is not easy to say. Transparent baler tape is the best baler tape. The quality of the baler belt depends entirely on the purity of polypropylene, and the higher the purity of polypropylene, the better the tension of the baler belt.

Contact us for more information about PP packing tape.

Features of pp strapping band making machine:

- Product Name: PP Strap Band Extrusion Line

- Material: PP Polypropylene New Material/recycled Material

- Inverter: 37KW(INVT)

- Equipment layout diagram: Customized

- Overall dimensions: L36*W2.0*H4.0M

- Solid state relay: Taiwan Fotek

Technical Parameters of pp strapping band making machine:

| Product Name: |

PP Strapping Band Extrusion Line |

| Polypropylene Band Production Line: |

220-300kg/h |

| Equipment Layout Diagram: |

Customized |

| Winding Method: |

Manual/automatic |

| Switches: |

Schneider |

| Inverter: |

37KW(INVT) |

| Solid State Relay: |

Taiwan Fotek |

| Strap Width: |

5-19mm |

| Electrical Appliances: |

Schneider |

| Thermostat: |

Taiwan Fotek |

Applications of pp strapping band making machine:

This Polypropylene Band Extrusion Line is suitable for various occasions and scenarios, such as:

- Manufacturing plants that require strapping bands for packaging and securing products.

- Warehouses that need to bundle and seal products for shipping or storage.

- Logistics companies that require a cost-effective solution for securing cargo during transportation.

- Retail stores that need to package and display products with an attractive and durable strapping band.

Support and Services:

The PP Strap Band Extrusion Line product comes with a comprehensive technical support and services package to ensure reliable and efficient operation. Our team of experienced technicians and engineers is available to provide on-site installation and commissioning, as well as training for operators and maintenance personnel. We also offer ongoing technical support and troubleshooting services to address any issues that may arise during operation.

Packing and Shipping:

Product Packaging:

- The PP Strap Band Extrusion Line will be securely wrapped in bubble wrap to prevent any damage during transportation.

- The wrapped machine will then be placed in a sturdy wooden crate for added protection.

- The crate will be sealed and labeled with the necessary shipping information.

Shipping:

- The PP Strap Band Extrusion Line will be shipped via sea freight.

- Shipping will be arranged by the manufacturer or their appointed agent.

- The customer will be provided with a tracking number once the machine has been shipped.

- The estimated shipping time will be communicated to the customer prior to shipment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews