Packaging machinery PP PET packaging tape automatic wrapping machine for servo motor control

Product Description of Automatic winding machine:

The automatic winding machine is a winding machine suitable for the PP PET strapping industry, with PLC control to reduce manual operation.

Working Conditions: Voltage 220V, Air Pressure 5--8kgf, Connect mark (Φ10) on machine with windpipe,

Main functions: 1) Use servo motor to arrange the wires, and reel in 9--32MM width strapping tape. Select the corresponding width of the tape through the touch screen for reeling, and there is no need to manually replace the transmission gear.

Mode: 2) Both with and without paper core are available.

After winding, the machine stops automatically, replaces the paper tube, cuts the strapping tape, fixes the strapping tape head with a clip, and automatically winds the tape. The whole process is completed automatically. For winding without paper core: directly wind on the 6-part air expansion plate, and the inner circle automatically wraps a 150mm wide tape to fix the innermost layer of strapping tape so that it will not fall apart when unloading.

Servo motor: 3) The winding shaft uses a servo reduction motor. The speed of winding is adjusted by the angle position control of the tension arm. The tension can be adjusted by the pressure of the tension arm cylinder, so that strapping tapes of different gram weights or widths can be wound with appropriate tension, minimizing the bending deformation of the strapping tape after winding.

Paper tube:4)Ø406mm*152mm,Ø406mm*190mm,

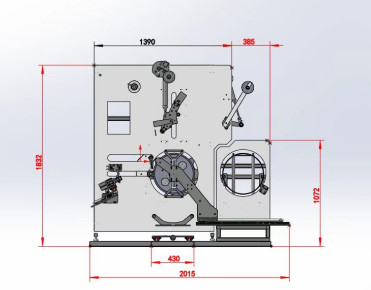

Technical Parameters of PET packing tape automatic winding machine:

| Name |

Automatic winding machine |

|

Strap Width

|

9-32mm |

| Adjustable tightness |

YES |

| Automatic winding |

YES |

| Application |

Packaging Industry |

| Winding method |

Automatic |

| Servo motor wiring |

YES |

| Touch screen control |

YES |

| Operation mode |

PLC Computer Touch Screen |

Applications of PET packing tape automatic winding machine:

Touch screen: operation and display of various functions in the touch screen panel (winding length, weight, start, stop, interface switch, bandwidth selection, paper core height selection, etc.)

Strap width replacement does not require gear replacement, and the round-trip stroke is automatically calculated. Bandwidth spacing can be arbitrarily set through the touch screen.

The winding speed is synchronized by the displacement sensor of the swing arm to achieve constant tension winding.

Weight measurement, meter measurement,One-click button spring air expansion reel, 9-32MM bandwidth arrangement automatic calculation, side roller fitting guide belt winding, winding end face flat, uniform spacing.

Support and Services :

The automatic winding machine provides comprehensive technical support and services. Our experienced team of technicians can provide a variety of services, including:

Pre-sales:

1. Layout diagram.

2. Labor cost analysis.

After-sales service:

1. Water and electricity lines, circuit diagrams, etc. of the automatic winding machine.

2. Installation, commissioning and training of the automatic winding machine.

3. Maintenance service of the P automatic winding machine.

4. Regular maintenance and repair

4. Fault diagnosis

6. Software update and upgrade

7. Spare parts and accessories

8. Training and technical consultation

FQA:

Q:What are the specifications of the PET automatic wrapping machine:

A:Width: 9-32mm; Thickness: 0.35-1.2mm;

Q:What is the control motor of the PET automatic wrapping machine?

A:Servo motor control

Q:What is the speed of the PET automatic wrapping machine?

A:150-250 meters/minute

Q:What is the control method of the PET automatic wrapping machine?

A:PLC control system

Q:What is the transaction method of the PET automatic wrapping machine?

A:TT,LC, negotiable.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews