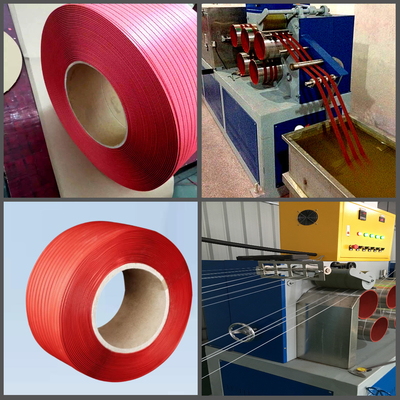

0.4-1.2mm Strap Thickness PP Strap Band Extrusion Line for Durable Packaging

Product Description of PP strap making machine

The PP Band Extrusion Production Line is equipped with Schneider switches and Taiwan Fotek solid-state relays that ensure the equipment's smooth functioning and high efficiency. The customized equipment layout diagram ensures that the production line is tailored to meet the specific requirements of the manufacturing unit.

The gearbox of the PP Strap Band Extrusion Line is manufactured by GUOMAO, a leading manufacturer of industrial gearboxes. The gearbox is designed to handle the high torque required for the extrusion process and ensures that the production line operates smoothly and efficiently.

The PP Strap Band Extrusion Line is equipped with a powerful 22 KW extruder that ensures consistent and high-quality output. The extruder is designed to handle a wide range of raw materials, making it highly versatile and adaptable to different manufacturing requirements.

Features of PP strip making machine

- Product Name: PP Strap Band Extrusion Line

- Video Outgoing-Inspection: YES

- Winding Method: Manual/automatic

- Strap Thickness: 0.4-1.2mm

- Inverter: INVT

- Material: PP Polypropylene New Material/recycled Material

This PP Strap Band Extrusion Line is also known as Polypropylene Strapping Band Extrusion Line or Strapping Band Production Line.

Technical Parameters of double output PP strap production line

| Product Name: |

PP Strap Band Extrusion Line |

| Material: |

PP Polypropylene New Material/recycled Material |

| Strap Strength: |

350-650kg |

| Production Capacity: |

125-150kg/h |

| Motor: |

Siemens |

| Electrical Appliances: |

Schneider |

| Switches: |

Schneider |

| Gearbox: |

GUOMAO |

| Equipment Layout Diagram: |

Customized |

| Equipment Voltage: |

Three-phase 380v /50Hz (Customized) |

Applications of PP strap band extrusion line

The PP Strap Band Extrusion Line, also known as the Polypropylene Band Extrusion Line, is a high-quality product designed to meet the packaging needs of various industries. The machine is manufactured by the top Chinese brand, PP STRAP MAKING MACHINE, with Model Number JTPP. The product is certified by IS CEO, ensuring that it meets all the required industry standards.

The machine is designed to produce bands of various widths, ranging from 5mm to 19mm, which makes it suitable for a wide range of applications.

The PP Strapping Band Extrusion Line is ideal for use in a variety of scenarios and occasions, including:

- Manufacturing industries that require high-quality strapping bands for their products.

- Logistics and transportation companies that require secure packaging for their goods.

- Construction companies that require strapping bands for their building materials.

- Postal and courier services that require secure packaging for their deliveries.

The PP Strap Band Extrusion Line is easy to operate and comes with both manual and automatic winding methods. This makes it easy to use for both small and large-scale production. The machine comes with a thermostat from Taiwan Fotek, which ensures that the temperature is accurately controlled during the extrusion process.

Packing and Shipping

Product Packaging:

The PP Strap Band Extrusion Line will be securely packaged in a wooden crate to ensure the safety of the equipment during transit. The crate will be labeled with the product name, specifications, and destination address for easy identification.

Shipping:

The PP Strap Band Extrusion Line will be shipped via sea freight to the designated port of the customer's choice. The customer is responsible for arranging inland transportation from the port to their final destination. Shipping and handling fees will be calculated and included in the final price of the product.

FAQ:

Here are some frequently asked questions about our PP Strap Band Extrusion Line:

Q: What is the brand name of this product?

A: The brand name of this product is PP STRAP MAKING MACHINE.

Q: What is the model number of this product?

A: The model number of this product is JTPP.

Q: Where is this product manufactured?

A: This product is manufactured in China.

Q: Is this product certified?

A: Yes, this product is certified with IS CEO.

Q: What is the minimum order quantity for this product?

A: The minimum order quantity for this product is 1 set.

Q: Is the price negotiable?

A: Yes, the price is negotiable.

Q: How is the product packaged for delivery?

A: The product is packaged with plastic film for delivery.

Q: What is the delivery time for this product?

A: The delivery time for this product is 30-40 days.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews