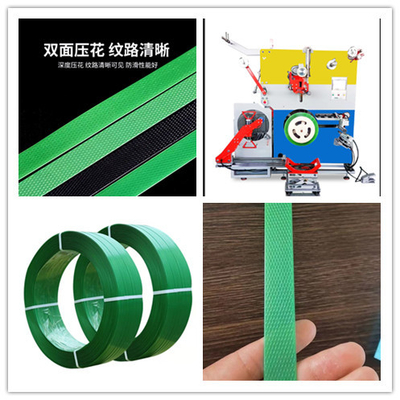

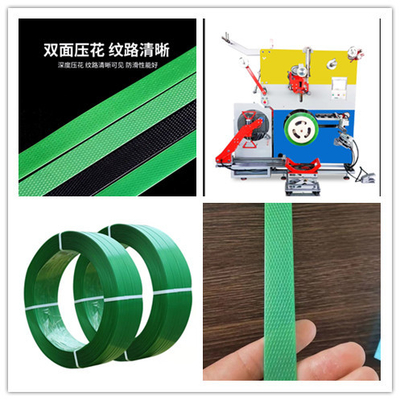

¢406mm * 150mm Paper Tube High strength and high tension PET bundling belt automatic winding and extrusion equipment

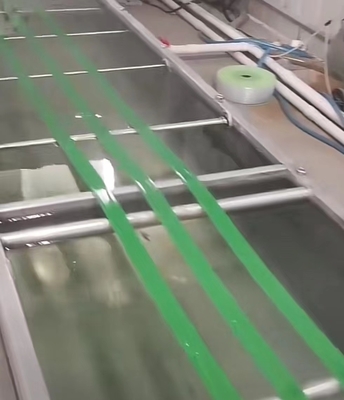

Product Description of PET strapping band making machine:

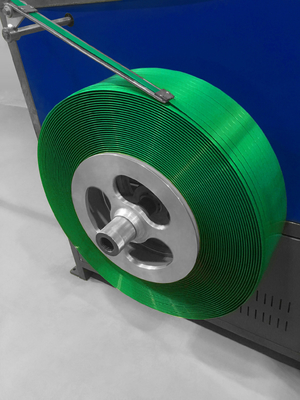

►The Strapping Band Winding Machine is a cutting-edge packing tape winder that enables customers to customize their size and wind width. It is equipped with a servo motor for automatic winding, providing a precise and consistent winding process. The range of strap width can be adjusted between 9-32mm. It is also capable of winding both PET strap and PP strap with dual-servo motors, making it a reliable and efficient PET strap full-automatic winder and PP Strap Winder.

►Main functions: 1) Use the servo motor to lay the cable, roll the 9~32MM wide packing belt, and select the corresponding bandwidth through the touch screen to roll, without manually changing the transmission gear.

►With paper core and without paper core, 2 modes are universal.

After the winding is completed, the machine will stop automatically, replace the paper tube, cut off the packing belt and clip the packing head to fix the packing head, and the winding operation will be carried out automatically, and the whole process will be completed automatically. For reeling without paper core: it is directly reeled on a 6-way air expansion disk, and the inner circle automatically winds a 150 mm wide tape to fix a layer of packing belt on the innermost circle, so that it does not scatter during unwinding.

►The winding shaft uses a servo reducer motor, and the speed during winding is adjusted by the angle position control of the tension arm. The tension can be adjusted by the pressure of the cylinder of the tension arm, so that the packing belts with different weights or widths can be wound with appropriate tension, and the bending deformation of the wrapping belt after winding is minimize.

►The exiting packing belt after winding is automatically moved to the extraction mechanism.

Features of PET strapping band making machine:

- Product Name: Strapping Band Winding Machine

- Power Consumption: 1.8KW

- Application: Packaging Industry

- Touch screen control: YES

- PLC, touch screen: Xinjie

- Auto wrap PE film: YES

- Servo winding machine

- Automatically stop the winder

- Servo winding machine

- PET packing belt automatic winder

- PET packing tape servo automatic winder

- PET strapping band making machine

Technical Parameters of PET strapping band making machine:

| Parameter | Value |

|---|

| Moment mode | YES |

| Air pressure | 4-7kgf |

| Paper tube | ¢406mm * 150mm |

| Automatic stop | YES |

| Adjustable tightness | YES |

| Operation mode | PLC Computer Touch Screen |

| Winding method | Automatic |

| Servo motor wiring | YES |

| No manual volume change is required | YES |

| Warranty | 12 Months |

| Type | Servo motor line automatic winding machine, PET automatic winder, PET STRAP WINDER DUAL-SERVO MOTOR |

Applications of PET strapping band making machine:

►The Automatic PET packing and winding machine (Model Number: JTPP/PET), manufactured by Automatic, is a great choice for businesses that need a reliable, high-performing PP strap full-automatic winder. With its adjustable tightness and dual-servo motor, the Automatic PET packing and winding machine allows for automatic winding with a strap thickness of 0.4-1.2mm and no manual volume change is required. And, with its automatic stop feature, you can be sure that your straps will be wound to exact specifications. The Automatic PET packing and winding machine is the perfect solution for any business that needs reliable and efficient PP strap winding.

►Shenzhen Jiatuo Plastic Machinery Co., Ltd. is committed to providing customers with complete and integrated plastic packaging belt production and investment one-stop solutions, providing timely, professional and effective services, has been successfully promoted to Southeast Asia, Europe and other countries and regions, and has been highly praised by users. The company has established long-term cooperative relations with many large enterprises in China, providing customers with high-quality products. The company has an experienced technical management team, sales team, R & D team, after-sales team, production team, etc., we continue to develop and improve, so that each step of the production process of packaging and production equipment are standardized and simplified, so that customers really feel "simple operation, high production capacity, low energy consumption, high quality." The packaging and belt production equipment produced by the company are produced and used by themselves before they are produced for export, and the products are currently well received in China.

Customization of PET strapping band making machine:

Strapping Band Winding Machine

Brand Name: Automatic PET packing and winding machine

Model Number: JTPP/PET

Place of Origin: CHINA

Size: Customized

Speed: 220-350m/min

Name: Automatic Winding Machine

Automatic paper tube change: YES

Adjustable tightness: YES

Highlighted Features: Automatic winding machine, Servo motor line automatic winding machine, Servo motor line automatic winding machine

Support and Services of PET strapping band making machine:

Strapping Band Winding Machine Technical Support & Services

We provide comprehensive technical support and services for our Strapping Band Winding Machine, so you can get the most out of your product.

Technical Assistance

Our technical team is available to answer any questions you may have during installation, operation, maintenance, and troubleshooting. We can assist you with product selection, installation and setup, and provide advice on best practices for your unique application.

Remote Support

We offer remote support for our Strapping Band Winding Machine. We can remotely view and control your machine, diagnose and resolve technical issues, and provide training and guidance to get the most out of your product.

On-Site Support

If you require on-site technical support, we can dispatch a qualified technician to your location to assist with installation, maintenance, and troubleshooting. Our technicians will provide hands-on support to ensure your product is running at its best.

Packing and Shipping of PET strapping band making machine:

Packaging and Shipping

The Strapping Band Winding Machine will be packaged securely for safe delivery. All components are shipped in a single package, and any necessary accessories are also included. To ensure the safety of the product during transport, all packaging materials are reinforced with bubble wrap, foam, and other protective measures.

The Strapping Band Winding Machine is shipped via a reputable courier service, and can be tracked online. Customers will be provided with the tracking information after the product has been dispatched.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews