5-19mm Strap Width Polypropylene Strapping Band Extrusion Line - Automatic winder 6000KGS/24H

Product Description of pp strapping band making machine:

►The Polypropylene Band Extrusion Line is an advanced and efficient strapping equipment, which is environmentally friendly and highly durable. It adopts INVT inverter to control the thickness of the strap in the range of 0.4-1.2mm. The product has a beautiful and generous appearance, and can withstand cold and high temperature conditions.

►The Polypropylene Band Extrusion Line is equipped with advanced technology, which can effectively improve the production efficiency and reduce the labor intensity. It is reliable and durable, with low energy consumption, and can be used for a long time.

►The Polypropylene Band Extrusion Line is suitable for the production of a variety of polypropylene straps with different thicknesses. It has high production output and low failure rate, and is widely used in the production process of various industries.

►Shenzhen Jiatuo Plastic Machinery Co., Ltd. is a domestic packaging belt production line special patent manufacturers, strong scientific and technological strength. Now, its self-developed new PP packaging belt production line, PET plastic steel belt production line is integrated with high-tech intelligent elements, to achieve the scientific concept of energy saving and environmental protection. The new PP packing belt production line is mainly composed of extruder, sink, extension machine, shaping machine, winding machine, etc. It has many advantages such as small elongation of bundling belt, excellent high temperature resistance, beautiful appearance, no rust and low cost. And because of its fully automatic technology, so the cost of manpower is very little, when working, a worker can guard 4-6 work lines, basically achieve unmanned. It is also because the company continues to develop in practice, the high-tech elements continue to be integrated into the product, so its production of packaging equipment has been well received by the majority of customers.

Features of pp strapping band making machine:

- PP Strap Band Extrusion Line

- Polypropylene Band Production Line

- PLC Touch Screen Control System

- Production Capacity: 200-300kg/h

- Screw: 110*3300mm

- Strap Width: 5-19mm

- Automatic winder

- PP polypropylene extrusion equipment

- Packaging tape manufacturing equipment

- Strong and durable

- Advanced technology

- Service guaranteed

- Beautiful and generous

Technical Parameters of pp strapping band making machine:

| Parameter |

Value |

| Name |

PP Environment-friendly strapping equipment |

| Environment-friendly strapping equipment |

YES |

|

Screw

|

Ø110*3300mm |

|

Host inverter

|

37KW (INVT)

|

|

Main motor

|

37KW(Siemens)

|

|

Screen changer

|

Replace the filter without cutting off the machine power supply

|

|

Winding method

|

manual/automatic

|

|

Number of tapes

|

4 |

| Total Power |

100KW |

| Gearbox |

GUOMAO |

| Cold and high temperature resistance |

YES |

| Beautiful and generous |

YES |

| Neat winding |

YES |

| Overall dimensions |

L36*W2.0*H4.0M |

|

Screw Material

|

38CrMoALA

|

| The equipment voltage |

Three-phase 380v /50Hz ( Customized ) |

| Video outgoing-inspection |

YES |

|

Capacity /24H

|

5-6T |

Applications of pp strapping band making machine:

The PP Strap Band Extrusion Line from JIATUO CHINA with model number JTPP-110 is certified by IS CEO and comes with a minimum order quantity of 1 SET. The price is Negotiable and the product is packed in plastic film. Delivery can be expected within 30-40days. This product is designed for maximum beauty and generosity and comes with a production capacity of 200-300kg/h and total power of 100KW. It can provide neat winding. The product is highly reliable and has earned a good reputation in the industry.

Customization of pp strapping band making machine:

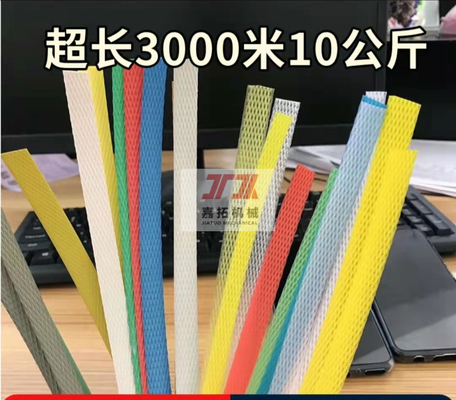

Are you looking for a high-performance PP Band Extrusion Production Line? JIATUO CHINA offers you the best PP Band Extrusion Line with model number JTPP-110 that is certified with IS CEO. The PP Strapping Band Extrusion Line has a low failure rate and overall dimensions of L36*W2.0*H4.0M. The colors of the line can be customized and the screw material is made of the superior 38CrMoALA. The minimum order quantity for this product is 1 set and the price is negotiable. We also provide the best packaging details with plastic film and delivery time of 30-40days.

Support and Services of pp strapping band making machine:

Technical Support and Services for PP Strap Band Extrusion Line

We offer comprehensive technical support and service for our PP Strap Band Extrusion Line to ensure optimal performance and long-term operation. Our team of experienced engineers and technicians are available to provide you with the following services:

- Troubleshooting and technical support

- On-site installation and commissioning

- On-site training and instruction

- Preventative maintenance and system optimization

- Repair and replacement of parts

If you have any questions about our PP Strap Band Extrusion Line or would like to learn more about our technical support and service offerings, please contact us at your convenience.

Packing and Shipping of pp strapping band making machine:

The PP Strap Band Extrusion Line will be packaged and shipped in a sturdy wooden box with foam lining to ensure both safety and convenience during the delivery process. The product is also wrapped with plastic film to ensure it is free from dust and other environmental contaminants during the shipping process.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews