100-600KG/H PP packing belt making machine 5-19mm PP packing belt production line High-speed PP belt making machine

Product Description of PP packing belt making machine:

PP strapping equipment produces plastic raw materials:

1.recycled materials or mixed new materials can be used to produce strapping tapes, and calcium carbonate can be appropriately added according to customer conditions to reduce production costs, increase product profits, and break through market competitiveness.

2. The 5-19mm PP strapping belt produced by the PP strapping equipment is suitable for various fully automatic unmanned strapping machines at home and abroad.

3. The PP packing belt making machine has high output and low power consumption, and the finished product line speed can reach 220-300m/min.

Features of PP packing belt making machine:

- Product Name: PP packing belt making machine

- Material barrel 180KG 1set

- Feeder: 2 sets

- Gearbox model: 225

- Screw: 125*3750mm

- Motor power: 45kw (Siemens)

- Screen changer: 180 type (can change the screen without stopping)

- Discharge die: one out four die or one out six die

- Water cooling tank:4000*450*500mm

- Causing machine 1set

- Specification of five-roller drum:240*250mm

- Extension oven specification (mm): 4000*470*880

- Embossing wheel: 156*150*198mm

- Double station winder: 4 sets

- Paper core specification: ¢200*180mm

- Strap Core Type: Paper/Plastic

- Power Consumption: 130KW

- Video outgoing-inspection: Provided

- Name: PP Strap Making Machine

- Warranty: 1 Year

- Feeding machine:1set

- Plastic Strap Production Machine

- High speed intelligent PP packaging belt production equipment

- PP extruder equipment

- PP polypropylene packing tape equipment

- Tape packing equipment

Technical Parameters of PP packing belt production equipment:

| Parameter |

Specification |

| Plastic Processed |

PP |

| Strap Color |

Red/ Green/ Black/ Yellow/ White |

| Power Supply |

380V/220V/440 |

| Video outgoing-inspection |

Provided |

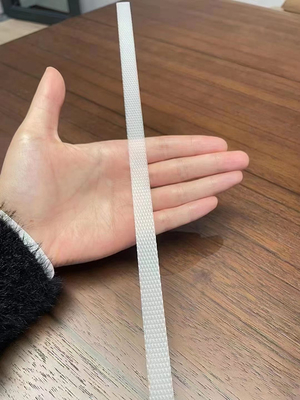

| Strap Thickness |

0.4-1.2mm |

| Motor |

Siemens |

| Strap Speed |

>250m/min |

| Strap Core Type |

Paper/Plastic |

| Strap Tension |

Adjustable |

|

Gearbox model

|

225 |

|

Screw

|

135*3750mm |

|

Motor power

|

45kw (Siemens)

|

|

Host inverter

|

45kw (INVT)

|

|

Double station winder

|

4 sets

|

|

Paper core specification

|

¢200*180mm

|

| Name |

Polypropylene Banding Machine, Polypropylene Strap Manufacture Equipment, PP Banding Machine Manufacturing Machine. |

Applications of PP packing belt making machine:

The JIATUO CHINA Polypropylene Banding Machine, model JTPP110, is a top-of-the-line Polypropylene Strap Making Machine. It is certified with IS CEO, and comes with a 1 year warranty. Its screw diameter is 110*3300mm, and it can make straps with a thickness of 0.4-1.2mm. A video outgoing-inspection is also provided. It has been designed with the latest Germany Japan technology, and makes it possible to produce high-quality polypropylene straps. The minimum order quantity for this machine is 1 SET, and the price is negotiable. The machine is shipped with plastic film packaging, and the delivery time is 30-40days.

① Feeding →② stirring →③ pre-drying →④ melting and measuring extrusion →⑤ embryo (belt embryo) cooling and forming →⑥ oven preheating →⑦ primary stretching →⑧ secondary stretching →⑨ embossening → oven tempering and setting → cooling → finished product winding

Customization of PP packing belt making machine:

PP Strap Making Machine

Customization Service

Brand Name: JIATUO CHINA

Model Number: JTPP135

Place of Origin: CHINA

Certification: ISO CEO

Minimum Order Quantity: 1 SET

Price: Negotiable

Packaging Details: plastic film

Delivery Time: 30-40days

Strap Width: 5-19mm

Motor: Siemens

Key Selling Points: Lead To Germany Japan Technology

Applicable raw materials: Recycled Material And Polypropylene

Strap Color: Red/ Green/ Black/ Yellow/ White

Plastic Strap Production Machine

Our PP Strap Making Machine is designed and developed with the best quality components and parts. It can produce plastic straps in various widths and colors, and is ideal for the production of polypropylene straps. It is equipped with a Siemens motor and lead to Germany Japan technology, making it highly efficient and reliable. The machine is also suitable for the production of straps using recycled material and polypropylene, and it has a minimum order quantity of 1 set.

Support and Services of PP packing belt making machine:

PP Strap Making Machine Technical Support and Service

Our team of technicians is available to provide assistance in the installation, commissioning and maintenance of your PP Strap Making Machine. We are committed to providing technical support and service to our customers throughout the lifetime of their machines.

We provide comprehensive training to our customers, helping them to get the most out of their machine. Our technicians can also provide onsite support as required.

We offer a range of support packages which include regular maintenance visits, spare parts, and access to our technical experts. We also provide remote access to our technical support team, giving customers access to our team of experts from any location.

We are committed to providing our customers with the highest level of technical support and service. Our team is highly experienced and knowledgeable in the PP Strap Making Machine, and we are always available to answer any questions or provide assistance when required.

Packaging and Shipping - PP packing belt making machine:

The PP packing belt production equipment is packaged to protect against damages during shipping. The packaging materials used are corrugated boxes, stretch films, and cushioning materials such as bubble wraps and foam. The machine is secured within the packaging material to prevent movement or shifting during transport.

The PP packing belt production equipment is shipped by air or sea depending on the customer's requirements. The delivery time will depend on the customer's location and the shipping method chosen. All shipments are tracked to ensure timely delivery.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews