Single Screw PP Strap Band Making Machine With Automatic Feeding System And Winder

Production description of PP strap band production machine

This production line is used for making full automatic PP strapping band and manual PP strap band for packing use. The width of the strap band is 5-19 mm, thickness is from 0.4-1.2 mm.

Packing belt equipment adopts 38CrMoALA extruderespecially suitable for high-grade packing belt production, extruder hopper type dehumidifying drying system and automatic feeding system, make the performance of the extruder is more stable, the unit all adopts frequency conversion motor drive and automatic intelligent temperature control system, realize the energy saving effect greatly.

Compositions

PP belt production line:

| 1 |

Vacuum feeder |

1 set |

| 2 |

Hopper dryer |

1 set |

| 3 |

Feeding machine |

2 set |

| 4 |

¢110 Extruding Machine |

1 set |

| 5 |

Automatic Screen filter changer |

1 set |

| 6 |

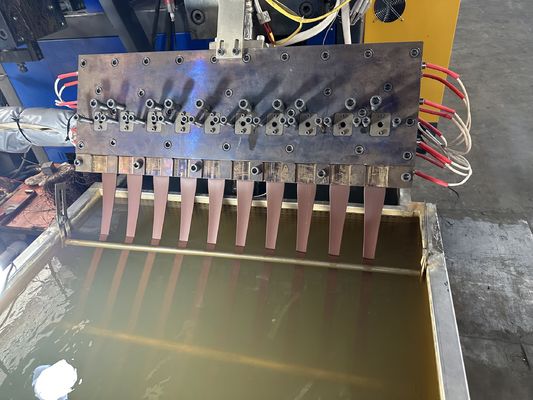

Mould(1 mould for 4 output) |

1 set |

| 7 |

Water cooling tank system |

1 set |

| 8 |

The first haul-off device |

1 set |

| 9 |

Stretching oven |

1 set |

| 10 |

The second haul-off device |

1 set |

| 11 |

PLC electrical control system |

1 set |

| 12 |

Embossing machine |

1 set |

| 13 |

Forming oven |

1 set |

| 14 |

Cooling system |

1 set |

| 15 |

The third haul-off device |

1 set |

| 16 |

Double disk winder |

4 set |

Features

PP strap band production machine:

- Special design hot forming tensile tank to make good gorming,euqal width,straight strap.

- Use 100% recycled pet/pp flakes to reduce the cost

- Can equip Siemens PLC control, or designed according to customer's requirements

- Unique oven hot air circulation mode make full use of thermal energy to reduce power loss

- special high efficiency stainless steel electric heating tube, heating quickly and durable

- Large extrusion volume, high hardness and high wear resistance

Application

PP packing straps making machine:

Materials: PP material, or 100% recycling pp flakes and granules.

This machine can be used to meet the needs of cartons, tobacco, clothing, paper, electronics, wooden boxes, fruit, electrical (such as refrigerators, washing machines, color TV), food and other industries.Based on the reinforced strapping band unit, is specially used for the top-grade light weight products with good quality, light gram weight and well rigidity. Its high-speed low-temperature stretching technology and optimized structure may reduce energy consumption to the maximum extent, simplify operating procedure and realize digital displayed accurate control. The unit has advantages of energy saving, great extrusion pressure, optimal embossing effect, high output, good formation, convenient maintenance, simple operation, safety and reliability. The single-band unit is an ideal device that is used to manufacture top-grade light weight strapping band. This unit is applicable to PP fresh material and used for producing light weight strapping band.

FAQ

Q1:What about the payment terms?

A1:Always 30% down payment as deposit,70% balance pay before shipping.

Q2:What about the payment way?

A2:TT,L/C at sight or MIC trade assurance.

Q3:If you will send engineer coming to our factory to install and test the machines?

A3:Yes,Every set of machine we will send professional engineer to your factory and help installation and test the machines for you.

Q4:If you have CE,SGS,ISO certificate?

A4:Yes,except these,if you also need other certificates,we also can help to apply.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews