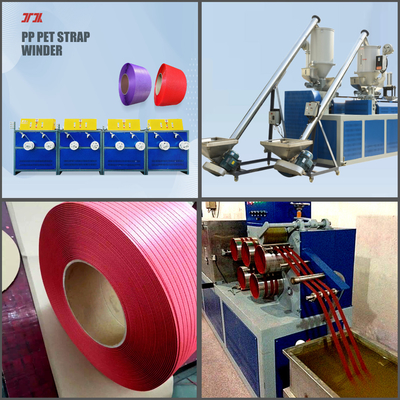

PP strapping band making machine 5-19mm PP PET automatic strapping band production line

Quick Detail Of PP Strap Making Machine

Name: PP 1 to 4 strapping production line

Model number: JTPP-110

Applicable raw materials: New PP particles, PP recycled materials, PP crushed materials

Number of screws: 1 Screw

Number of extruded belts: 4

Width range: 5-19mm

Thickness range: 0.4-1.2mm

Production capacity: 200kg/h

Installation size: L38*W2.0*H4.0(m)

Raw materials:

100% polypropylene new material or recycled material

Configuration Of PP Strapping Production Line

| NO. |

Name |

QTY |

| 1 |

Color Mixer |

1 set |

| 2 |

Vacuum feeder or screw loader feeder

(100% raw material use vacuum feeder machine;recycled material use screw loader feeder machine) customer choose one of it. |

1 set |

| 3 |

Hopper dryer |

1 set |

| 4 |

SJ single screw extruder |

1 set |

| 5 |

High speed Screen exchanger device |

1 set |

| 6 |

Molud |

1 set |

| 7 |

Water cooling tank |

1 set |

| 8 |

The first traction machine- 5 rollers |

1 set |

| 9 |

The first Stretch forming oven |

1 set |

| 10 |

The Second traction machine- 5 rollers |

1 set |

| 11 |

The second Stretch forming oven |

1 set |

| 12 |

The Third traction machine- 3 rollers |

1 set |

| 13 |

Embossing machine |

1 set |

| 14 |

The Winder machine |

1 set |

Features of PP strapping equipment

High degree of automation: reduce manual intervention, improve efficiency, PLC control, easy debugging.

High production efficiency: continuous production, large output, 24-hour non-stop production.

Stable product quality: automated control ensures consistency of extrusion specifications, suitable for high-end strapping machines.

Features of the oven:

1. There is a high-power heating tube inside the oven, and the hot air circulation method makes full use of heat energy to reduce power loss.

2. High-temperature resistant silicone seals keep the oven super tight

3. Special high-efficiency all-stainless steel electric heating tube, fast heating, long-lasting and durable

4. Reheating makes the PP strapping tape shrink in the oven, and the straightness of the strapping tape produced is more standardized and the shrinkage rate is smaller.

FAQ

Q:What is the voltage of PP strapping equipment?

A:380V/50HZ, we support customization

Q:What is the length of the PP strapping tape??

A: L:36 M.

Q:Where is the PP strapping equipment produced?

A:We are from China.

Q:Can PP strapping equipment provide after-sales service?

A:Yes, we have professional after-sales engineers who provide 24-hour online guidance.

Q:Is the quality of PP strapping equipment stable?

A:We have 30 years of manufacturing experience, and have their own PP packaging belt production plant, equipment quality is stable, the process is worth choosing.

Q:Does PP strapping equipment support customization?

A:We are a manufacturing plant that can customize model size, extrusion capacity, voltage and so on according to customer requirements.

Q:What does the wrapping machine part of the PP strapping equipment look like?

A:Equipped with automatic wrapping machine/semi-automatic wrapping machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews