Name: PP 1 to 4 strapping production line

Model number: JTPP-110

Applicable raw materials: 100%recycled materials or PP polypropylene new materials to produce strapping tape;

Number of screws: 1 Screw

Number of extruded belts: 4

Width range: 5-19mm

Thickness range: 0.4-1.2mm

Production capacity: 200kg/h

Installation size: L38*W2.0*H4.0(m)

Configuration Of PP Strapping Production Line

| NO. |

Name |

QTY |

| 1 |

Color Mixer |

1 set |

| 2 |

Vacuum feeder or screw loader feeder

(100% raw material use vacuum feeder machine;recycled material use screw loader feeder machine) customer choose one of it. |

1 set |

| 3 |

Hopper dryer |

1 set |

| 4 |

SJ single screw extruder |

1 set |

| 5 |

High speed Screen exchanger device |

1 set |

| 6 |

Molud |

1 set |

| 7 |

Water cooling tank |

1 set |

| 8 |

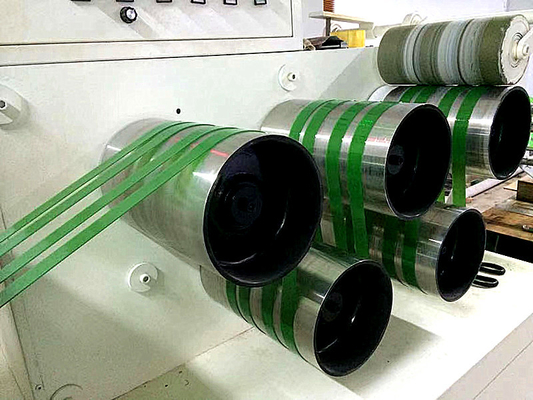

The first traction machine- 5 rollers |

1 set |

| 9 |

The first Stretch forming oven |

1 set |

| 10 |

The Second traction machine- 5 rollers |

1 set |

| 11 |

The second Stretch forming oven |

1 set |

| 12 |

The Third traction machine- 3 rollers |

1 set |

| 13 |

Embossing machine |

1 set |

| 14 |

The Winder machine |

1 set |

About After-sales:

We provide comprehensive technical support and service for our PP Strap Making Machine. Our team of experienced technicians can provide a variety of services, including:

Pre-sales:

1.Layout plan of PP belt making machine.

2.Analysis of the cost of PP tape making machine.

3.Raw materials that can be used for PP tape making machine.

After-sales service:

1.Water and electricity circuits of PP belt making machine, circuit drawings, etc.

2.Installation, commissioning and training of PP belt making machine.

3.Maintenance service of PP belt making machine.

4.Regular maintenance and repair

5.Troubleshooting and diagnosis

6.Software updates and upgrades

7.Spare parts and accessories

8.Training and technical advice

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews