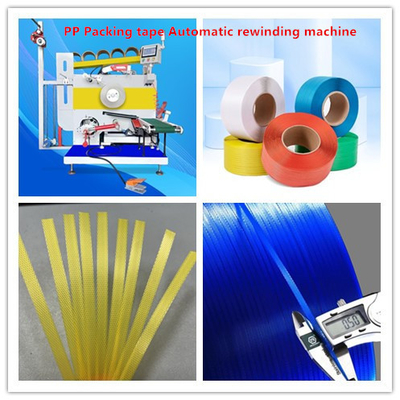

Plastic machinery PP strapping production line PLC control system, equipped with automatic servo wrapping machine

Product Description of pp strapping roll manufacturing machine:

1 Production capacity: 100-600kgs/hour, different extrusion capacities correspond to different models.

2 Materials: A variety of materials can be processed, such as new PP materials, recycled PP materials, granular materials, etc.

3 Control system: Full-line PLC automatic control, convenient specification debugging;

4 Screw: Extruder-specific screw, high plasticizing strength, barrel design adopts gradual change, the latest reduction ratio to improve plasticizing effect and stabilize output;

5.Screen changer: It uses a large-area filter with four-net circulation, and can produce 24 hours without stopping.

6 After-sales service: Support overseas service, installation, employee training and technical support.

Features of pp strapping roll manufacturing machine:

- Product Name: PP Strap Making Machine

- Number of tapes:2-12 tapes

- Model:JTPP-90-135

- Screw:¢190/100/110/125/130/135mm

- Language:Chinese/English/Vietnamese/Thai (customizable)

- Strap Tension: Adjustable

- Wrapping machine: Semi-automatic/fully automatic wrapping machine

- container :40GP*2

- Used for producing plastic strapping for packaging, such as: Polypropylene Strapping Machine and Plastic Strapping Manufacturing Machine

Technical Parameters of pp strapping roll manufacturing machine:

| Name |

Parameters |

|

Model

|

JTPP-125 |

| Strap Speed |

>250-300m/min |

| Strap Width |

5-19mm |

| Strap Material |

PP Recycle Material/New Raw Material |

|

StrapThickness

|

0.3-1.2mm |

| Power Supply |

380V/220V/50hz(Negotiable0 |

|

Operator

|

2-3people |

|

Manual/automatic

|

2sets |

|

Overall dimensions

|

(L)36*(W)2*(H)4 m |

|

Machine weight

|

12-13T |

Applications of pp strapping roll manufacturing machine:

1 Production capacity: 100-600kgs/hour, different extrusion capacities correspond to different models.

2 Materials: A variety of materials can be processed, such as new PP materials, recycled PP materials, granular materials, etc.

3 Control system: Full-line PLC automatic control, convenient specification debugging;

4 Screw: Extruder-specific screw, high plasticizing strength, barrel design adopts gradual change, the latest reduction ratio to improve plasticizing effect and stabilize output;

5 After-sales service: Support overseas service, installation, employee training and technical support.

After-sales service:

We provide comprehensive technical support and service for our PP Strap Making Machine. Our team of experienced technicians can provide a variety of services, including:

Pre-sales:

1.Layout plan of PP belt making machine.

2.Analysis of the cost of PP tape making machine.

3.Raw materials that can be used for PP tape making machine.

After-sales service:

1.Water and electricity circuits of PP belt making machine, circuit drawings, etc.

2.Installation, commissioning and training of PP belt making machine.

3.Maintenance service of PP belt making machine.

4.Regular maintenance and repair

5.Troubleshooting and diagnosis

6.Software updates and upgrades

7.Spare parts and accessories

8.Training and technical advice

FAQ:

Q&A for PP Strap Making Machine

Q1: What is the voltage of the PP belt making machine?

A1: 380V/50HZ, three-phase, can be customized.

Q2: What is the model number of the PP Strap Making Machine?

A2: JTPP.

Q3: Where is the PP Strap Making Machine manufactured?

A3: CHINA.

Q4: What is the minimum order quantity for the PP Strap Making Machine?

A4: 1 SET.

Q5: How is the PP Strap Making Machine packaged?

A5: The PP Strap Making Machine is packaged with plastic film.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!