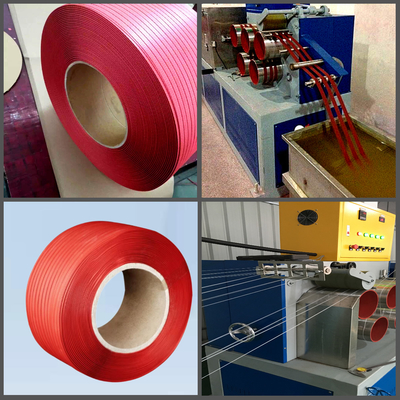

Polypropylene belt production line, PP belt extrusion production line,37KW Siemens motor, low failure rate

Product Description of pp strapping band making machine:

1. Raw materials-----PP strapping equipment can produce plastic raw materials: recycled materials or PP polypropylene new materials to produce strapping tape;

2. Screw-----The equipment adopts high-precision high-quality screws, adopts well-known brands, and has unique parameter design. It has the advantages of large extrusion volume, good plasticization, high hardness and wear resistance; equipped with a quantitative extrusion system, the width and thickness of the produced belts are the same, the error range is small, and it meets the national strapping tape acceptance standards;

3. Automatic screen changer------Equipped with a non-stop automatic screen changer, the screen does not need to be stopped, and the efficiency is maximized. 4-net circulation large-area filtration does not require frequent screen changes.

4. PLC system----The equipment adopts an intelligent PLC Chinese/English version control system, which is simple and easy to understand, beautiful and generous, sturdy and durable, long life, and low failure rate. The equipment has an exclusive parameter memory system, which can store data after each specification is produced, and the parameters can be directly adjusted during the next production.

Features of pp strapping band making machine:

- Product Name: PP Strap Band Extrusion Line

- Thermostat: Taiwan Fotek

- Equipment Voltage: Three-phase 380v /50Hz (Customized)

- Speed: Adjustable

- Barrel:150KG

- Strap Width:5-19mm

- Strap Thickness:0.3-1.2mm

- Control System: PLC Touch Screen Control

- Winding method : manual/automatic

Technical Parameters of pp strapping band making machine:

| Product Name: |

PP Strap Band Extrusion Line |

| Production Capacity: |

220-300kg/h |

| Material: |

PP Polypropylene New Material/recycled Material |

| Screw Material: |

110*3300mm |

| Gearbox: |

225# GUOMAO |

| Thermostat: |

Taiwan Fotek |

| Solid State Relay: |

Taiwan Fotek |

| Speed: |

Adjustable |

| Overall Dimensions: |

L36*W2.0*H4.0M |

| Equipment Layout Diagram: |

Customized |

Applications of pp strapping band making machine:

①PP one-out-two equipment extrude two lines at the same time: the production capacity is about 2.5 tons in 24 hours, and the whole production line requires 2 people to operate. The total length of the equipment is about: 28 long * 2 meters wide * 4 meters (highest part)

Equipment power: 80KW Operating power: 40-45KW

②PP one-out-three equipment extrude three lines at the same time: the production capacity is about 3.5 tons in 24 hours, and the whole production line requires 2 people to operate. The total length of the equipment is about: 30 long * 2 meters wide * 4 meters (highest part)

Equipment power: 90KW Operating power: 45-50KW

③PP one-out-four equipment extrude four lines at the same time: the production capacity is about 5-6 tons in 24 hours, and the whole production line requires 2-3 people to operate. The total length of the equipment is about: 35 long * 2 meters wide * 4 meters (highest part)

Equipment power: 100KW Operating power: 50-55KW

④PP one out of six equipment extrudes six lines at the same time: the production capacity is about 8-9 tons per 24 hours, and the entire production line requires 3-4 people to operate. The total length of the equipment is about: 40 meters long * 2 meters wide * 4 meters (highest part)

Equipment power: 130KW Operating power: 55-60KW

Support and Services:

The PP Strap Band Extrusion Line is a high-quality product that comes with comprehensive technical support and services. Our team of experts is available to provide you with any assistance you may need to ensure that your product is functioning optimally. Our technical support services include:

- Installation support

- Training and education

- Preventive maintenance

- Repairs and replacements

- On-site technical assistance

Packing and Shipping:

Product Packaging:

The PP Strap Band Extrusion Line will be packaged in a sturdy wooden crate to ensure its safe transportation. The machine will be secured and protected with foam padding and other cushioning materials to prevent any damage during shipping.

Shipping:

The PP Strap Band Extrusion Line will be shipped by sea or air, depending on the customer's preference. Our team will coordinate with the shipping company to ensure timely delivery and provide the customer with all necessary shipping documentation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!