Manual/Automatic PET Strap Making Machine with 2-8 Straps / 406*150mm Paper Core Diameter

Product Description of pet strap manufacturing machine:

Product Overview

The PET Strap Making Machine is an advanced and efficient machine used for producing PET Packing Strap Belt. It is equipped with a 45KW host inverter from INVT, ensuring high performance and energy saving.

Host Inverter

The machine is equipped with a 45KW host inverter from INVT, a leading brand in the industry. This powerful inverter ensures stable and efficient operation of the machine, making it a reliable choice for PET Strap production.

Strap Thickness

The PET Strap Making Machine is capable of producing straps with a thickness ranging from 0.6mm to 1.2mm, making it suitable for a wide range of packaging needs. Whether you need thin or thick straps, this machine can meet your requirements with ease.

Model

The machine has a model of 100*2900mm, providing a large production capacity. This means that you can produce a large quantity of PET Packing Strap Belt in a shorter amount of time, increasing your productivity and efficiency.

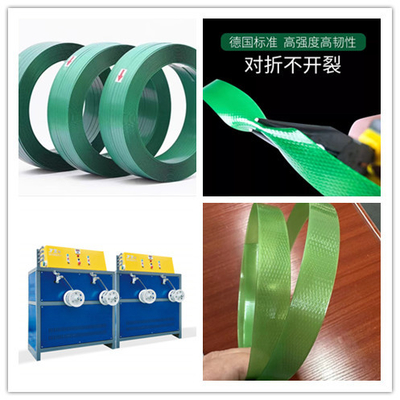

Final Product

The final product of the PET Strap Making Machine is PET Packing Strap Belt, a durable and strong packaging material. It is widely used in various industries such as shipping, logistics, and agriculture for securing and bundling goods.

Raw Material

The machine uses 100% recycled bottle flakes material as its raw material, making it an environmentally friendly choice. It can also use 100% broken material, reducing waste and contributing to a sustainable production process.

Energy Saving

The PET Strap Making Machine is designed to be energy efficient, making it cost-effective for businesses. The use of 100% recycled bottle flakes material also contributes to energy saving and reduces the carbon footprint of the production process.

High Efficiency

With its advanced technology and efficient design, the PET Strap Making Machine can produce PET Packing Strap Belt with high efficiency. This means that you can meet your production targets in a shorter amount of time, increasing your productivity and profitability.

Features of pet strap manufacturing machine:

- Product Name: PET Strap Making Machine

- Warranty: 1 Year

- Color: REQUIREMENT BY CUSTOMER

- Capacity: 300-350KG/H

- Final Product: PET Packing Strap Belt

- Type: PET Plastic Extrusion Machine

- Key Features: High-end intelligent, PLC control

- PLC control system

- Uses 100% recycled bottle flakes material

- High efficiency PET STRAP MACHINE

Technical Parameters of pet strap manufacturing machine:

| Technical Parameter | Description |

|---|

| Model | JTPET-100 |

| Type | PET Plastic Extrusion Machine |

Screw | 100*3000 |

| Warranty | 1 Year |

| Solid-state relay | Taiwan Fotek |

| Host inverter | 45KW(INVT) |

| Weight | 18000KG |

| Voltage | 380V/50HZ (customized) |

| Capacity | 300-350KG/H |

| Power | 45KW |

| Paper tube size | GUOMAO |

| PET STRAP | Can produce PET strap with high strength and good flexibility |

| SIMENS | Adopts high-quality SIMENS electric components for stable and reliable performance |

| Double cylinder / Single cylinder | Can be customized to have either double cylinder or single cylinder for different production needs |

| Schneider | Uses Schneider brand for electrical components for higher safety and stability |

Applications of pet strap manufacturing machine:

PET Strap Making Machine

Are you looking for a reliable and efficient way to produce PET plastic steel straps for your packaging needs? Look no further than the PET Strap Making Machine, the ultimate solution for all your PET strapping requirements.

| Product Information |

|---|

| Brand Name | PET plastic steel belt production equipment |

| Model Number | JTPET-100 |

| Place of Origin | China |

| Certification | ISO |

| Minimum Order Quantity | 1 set |

| Price | Negotiable |

| Packaging Details | Plastic film |

| Delivery Time | 30-40 days |

| Color | Customized |

| Host Inverter | 45KW (INVT) |

| Strap Thickness | 0.6-1.2mm |

| Final Product | PET Packing Strap Belt |

| Paper Tube Size | Guomao |

Customization of pet strap manufacturing machine:

PET Strap Making Machine Customization Service

Brand Name: PET Plastic Steel Belt Production Equipment

Model Number: JTPET-100

Place of Origin: CHINA

Certification: ISO CEO

Minimum Order Quantity: 1 SET

Price: Negotiable

Packaging Details: Plastic Film

Delivery Time: 50-60days

Width:9-32mm

Strap Thickness: 0.6-1.2mm

Weight: 18000KG

Product Name: PET Plastic Steel Belt Production Equipment

Solid-state relay: Taiwan Fotek

Warranty: 1 Year

Our PET Strap Making Machine offers customizable service to meet your specific needs. Our equipment is capable of using 100% recycled bottle flakes material to produce high quality PET straps. The SIMENS PLC control system ensures efficient and precise production. With our customizable service, we can tailor the machine to your desired specifications. Contact us now to learn more about our PET Strap Making Machine and how we can help improve your production process.

Packing and Shipping of pet strap manufacturing machine:

Packaging and Shipping for PET Strap Making Machine

Our PET Strap Making Machine is carefully packaged to ensure safe and secure delivery to our customers. Each part of the machine is wrapped with protective materials and packed in sturdy cartons.

The main machine body is packed in a wooden case to provide extra protection during transportation. All necessary accessories and tools are also included in the packaging.

For international shipments, the machine is loaded onto a pallet and covered with shrink wrap to prevent any damage during transit. The pallet is then securely strapped and labeled with the customer's information.

Once the machine is ready for shipping, it is delivered to our trusted logistics partner for transportation. We work with reputable shipping companies to ensure timely and efficient delivery to our customers.

Upon arrival at the destination, our customers can easily unpack and assemble the machine with the help of the included instruction manual. Our customer service team is also available to provide assistance if needed.

At PET Strap Making Machine, we take great care in packaging and shipping our products to ensure they arrive in perfect condition. Customer satisfaction is our top priority, and we strive to provide a seamless purchasing experience from start to finish.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!