Plastic Polypropylene PP Strap Band Extrusion Line Extruding Machine

plastic pp strapping band production line 260m/min PP strap extrusion machine/PP packing making machine

PET/PP strapping band dispenser extrusion machine / Polyester Strap Packaging Belts PP Strapping Band production line

Quick Detail Of PP Strap Making Machine

Name: PP 1 to 4 strapping production line

Model number: JTPP-110

Applicable raw materials: New PP particles, PP recycled materials, PP crushed materials

Number of screws: 1 Screw

Number of extruded belts: 4

Width range: 5-19mm

Thickness range: 0.4-1.2mm

Production capacity: 200kg/h

Installation size: L38*W2.0*H4.0(m)

| Model No. |

PP-2 |

PP-3 |

PP-4 |

PP-6 |

PP-8 |

PP-2-2 |

PP-2-4 |

| Production material |

PP Recycled /

raw material |

PP Recycled /

raw material |

PP Recycled /

raw material |

PP Recycled |

PP Recycled |

PP Recycled |

PP Recycled |

| Number of tapes |

2 |

3 |

4 |

6 |

8 |

4 |

6 |

Outgoing bandwidth

(mm) |

5~19 |

5~19 |

5~19 |

9~19 |

9~19 |

9~19 |

9~19 |

Outlet thickness

(mm) |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

Extrusion capacity

(kg/h) |

120 |

180 |

240 |

360 |

480 |

120 |

240 |

Maximum linear speed

(m/min) |

≥250 |

≥250 |

≥250 |

≥250 |

≥250 |

≥250 |

≥250 |

| PLC control system |

PLC control |

PLC control |

PLC control |

PLC control |

PLC control |

PLC control |

PLC control |

| Screw model |

90 |

100 |

110 |

125 |

135 |

90/65 |

110/75 |

| Reducer model |

200 |

200 |

225 |

250 |

280 |

200/173 |

225/173 |

| Automatic dryer hopper |

100KG |

100KG |

150KG |

200KG |

250KG |

100/100KG |

100/150KG |

| Screen changer |

Manual / Auto |

Manual / Auto |

Manual / Auto |

Manual / Auto |

Manual / Auto |

Manual / Auto |

Manual / Auto |

| Production capacity/24H |

2.8 tons |

4.3 tons |

5.7 tons |

8.6 tons |

11.5 tons |

2.8 tons |

5.7 tons |

Configuration Of PP Strapping Production Line

| NO. |

Name |

QTY |

| 1 |

Color Mixer |

1 set |

| 2 |

Vacuum feeder or screw loader feeder

(100% raw material use vacuum feeder machine;recycled material use screw loader feeder machine) customer choose one of it. |

1 set |

| 3 |

Hopper dryer |

1 set |

| 4 |

SJ single screw extruder |

1 set |

| 5 |

High speed Screen exchanger device |

1 set |

| 6 |

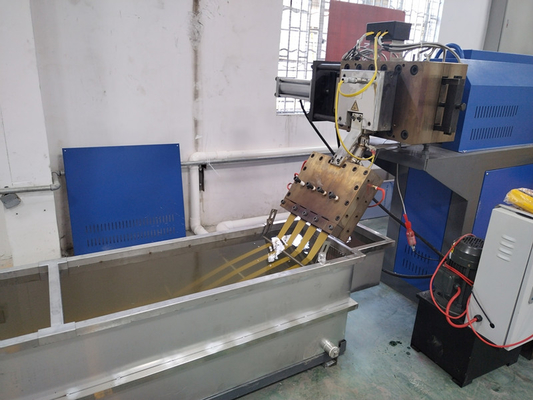

Molud |

1 set |

| 7 |

Water cooling tank |

1 set |

| 8 |

The first traction machine- 5 rollers |

1 set |

| 9 |

The first Stretch forming oven |

1 set |

| 10 |

The Second traction machine- 5 rollers |

1 set |

| 11 |

The second Stretch forming oven |

1 set |

| 12 |

The Third traction machine- 3 rollers |

1 set |

| 13 |

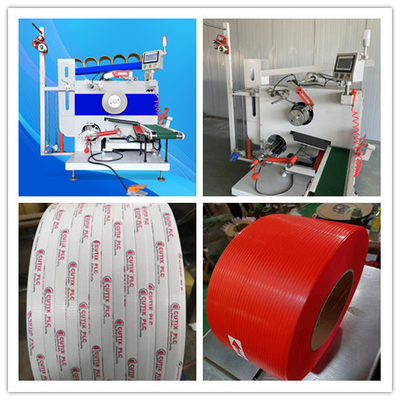

Embossing machine |

1 set |

| 14 |

The Winder machine |

1 set |

Features Of PP Strap Extrusion Line

Solemnly declare: This machine has been improved by our company and has core technology. It is inconvenient to upload detailed pictures and videos. Please forgive us. Welcome to visit and inspect.The machine shall prevail in kind.

PP PET packing belt production line features:

PP Plastic packing belt making machine PET strap tape extruding machine

1. Production of raw materials can be used to produce packaging belts with recycled materials or mixed new materials. It is also possible to add calcium carbonate according to customer conditions to reduce production costs, increase product profit, and market competitiveness.

2. The output is high, and the finished line speed can reach 260m/min.

3. The appearance of the whole machine has been optimized, beautiful and high-grade, durable and durable.

4. High-precision die parts make the product forming quality stable, width and thickness fluctuations are far less than the

national standard; unique network changing device greatly reduces the network changing time.

5. High-precision high-quality screw, using well-known brand, unique parameter design, with the advantages of large extrusion,good plasticization, high hardness and high wear resistance.

6. Configure special hardened gear reducer, high speed wear and long service life.

7. Unique design of correcting device to control product skewness.

8. Unique oven loop heating system, the internal reciprocating winding method, fully utilizing thermal energy to greatly reduce power loss.

9. Unique stretching process, with good rigidity and stable width.

10. Unique loop cooling system, multiple sets of guide roller, which makes the strap cooling and shrinking more complete, the product is more stable and the size is more accurate.

11. Five-roll traction system, the traction is stable, the equipment runs smoothly, the failure rate is reduced, and the

maintenance cost is reduced by 60%.

12. High-precision special embossing and pressing device, adjustable pressure, clear and beautiful embossing, improved product quality, comparable to Europe, America, Japan and South Korea.

13. Constant force winding system, unique design parameters, in line with high output, excellent tape winding effect, flat and beautiful section.

14. Wheel and shaft parts are made of high-strength alloy steel. The gears are processed by carburizing, quenching and grinding,and the equipment failure rate is reduced by 60%.

15. Using computer programming control system, automatic memory strapping production specification data, easy to operate, easy to debug.

16. The PP production line has four belts, and the stable production volume reaches 5-6 tons per day! The latest product PP production line has six belts, which is the first in the industry.

17. Optional no-stop automatic screen changer! Maximize benefits.

FAQ ABOUT PP STRAPPING BAND EXTRUSION LINE

1. For PP(polypropylene) strapping band extrusion line

* What about the output of PP strapping band extrusion line? 150kg/hr, 280kg/hr, 500kg/hr.

* What about the size of strap that the PP strap machine can make? Width: 5-25mm; Thickness: 0.35-1.0mm;

* What about the installation power of the PP strap machine? 135kw/155kw/195kw/439kw;

2. For PET(polyester) strapping band extrusion line

* What about the output of PET strapping band extrusion line? 200kg/hr, 400kg/hr, 600kg/hr, 800kg/hr.

* What about the size of strap that the PET strap machine can make? Width: 9-32mm; Thickness: 0.35-1.2mm;

* What about the installation power of the PET strap machine? 215kw/285kw/352kw/900kw;

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!