High-speed intelligent 300KG/PET plastic steel belt production equipment

Product Description of PET packaging belt production line:

1.The extruder uses a special PET screw with unique parameter design. The screw has a unique separation and mixing effe ect to ensure the uniform plasticization of the raw materials. It has the advantages of large extrusion, good plasticization,high hardness, high wear resistance, etc.

2.The three-dimensional folding super !arge area filter device, the unfolded area of the filter screen is 30 times larger than tl the area of the traditional flat filter screen; the filter mesh can reach 80 meshes, and the unique screen changing device greatly reduces the screen changing time and improves work efficiency.

3.The rotating honeycomb dehumidification drying system is used to dry the raw materials.

4.The dew point of -50°C ensures that the moisture content of the raw materials is ≤50PPM, and has the effect of solid-pha ase polycondensation and viscosity increase.

stable, and the width and thickness fluctuations are much smaller than national standards;

5.The equipment adopts a unique double-stretching process, which has good rigidity and stable width, which improves the t tensile strength of the finished product.

6.High-precision components make the product quality Unique oven circulating heating system, internal reciprocating winding method, making full use of heat energy to

greatly r reduce power loss.

7.ToThe unique circulating cooling system and multiple sets of shaping guide rollers make the packing belt cooler and shrinl nk more fully, the product is more stable, and the size is more accurate.

8.ToThe five-roller traction system has stable traction, makes the equipment run smoothly, reduces the failure rate, and red duces the post-maintenance cost by 60%.

9.ToThe high-precision special embossing and pressing device, the pressure is adjustable, the embossing wheel can be sy ynchronized up and down, the embossing is clear and beautiful, and the product quality is comparable to that of Europe, America, Japan and South Korea.Constant force rewinding system, unique design paramet ters, in line with high output, excellent reeling effect, flat and beautiful sides on both sides.

10.The rewinding machine adopts double-station rewinding device, which is easy to operate and easy to change the reel.

11.It can be produced entirely with 100% bottle flakes, and the quality of the finished product can be compared with brand ne ew materials.

Features of PET packaging belt production line:

- Product Name: PET Strap Making Machine

- Voltage: 380V 50HZ 3Phase(Customized)/440/220V

- Trademark: Jiatuo

- Strap Color: White/Black/Blue/Green Etc.

- Strap Core Material: Paper/Plastic/Aluminum

- Production Capacity: 300-400kg/h

- Equipment footprint: 60*2.0*7.0M

- The fuselage frame adopts :100*100*4.0 mm (pass national standard square)

- Paper core specification: ¢ 406*150mm

- Dimension of thread return shaft: ¢ 32*150mm (imported from Taiwan)

- Automatic: Yes

- PET STRAP: Yes

- 100% recycled bottle flakes material: Yes

Technical Parameters of PET packaging belt production line:

| Product Name |

PET Strap Making Machine |

|

Width range

|

9-32mm |

|

Thickness

|

6-1.2mm |

| Strap Tension |

300-1000kg |

| Trademark |

Jiatuo |

| Production Capacity |

300-350kg/h |

|

Applicable raw materials

|

PET bottle flake material, 100% broken material |

|

gross weight

|

20kg/reel

|

| Control System |

PLC Control |

|

20kg/reel

|

18.5kg/reel |

|

Paper tube size

|

406*150mm |

| Strap Color |

White/Black/Blue/Green Etc. |

|

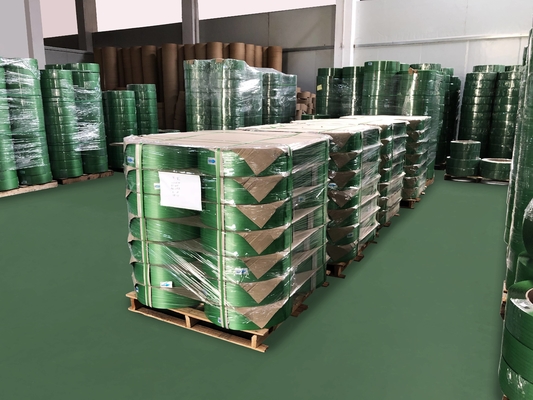

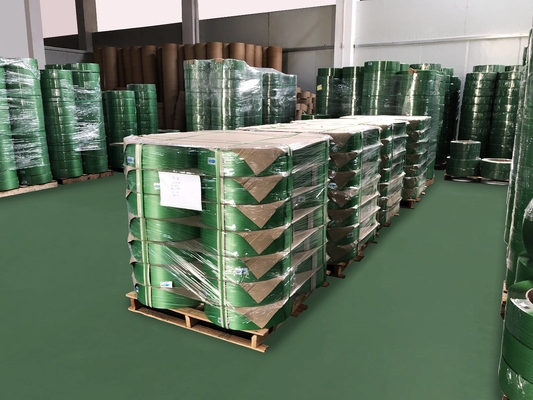

Packing method

|

PE film

|

|

Winder

|

Manual/automatic

|

| Special Feature |

Automatic, Memory Parameter, High Precision |

Applications of PET packaging belt production line:

Applications of PET packaging belt production line:

The JIATUO CHINA PET Strap Making Machine, with model number JTPET, is designed to produce plastic straps of various widths, from 9-32mm, for a variety of industries. Certified by IS CEO, the machine is available in minimum orders of 1 SET. Customers can expect a competitive price and their goods to be packaged in plastic film. Delivery time is usually within 30-40 days after order confirmation.

The PET strap making machine is powered by a SIEMENS brand motor and an INVT brand inverter, allowing for a strap speed of up to 250m/min. Its PLC control system is equipped with memory parameter and speed control functions.

The PET strap making machine is well-suited for use in brickyards, metal, steel, aluminum and brewery industries. It offers an efficient and reliable way for customers in these industries to produce plastic straps with precision.

Customization of PET packaging belt production line:

PET Strap Making Machine

- Brand Name: JIATUO CHINA

- Model Number: JTPET

- Place of Origin: CHINA

- Certification: IS CEO

- Minimum Order Quantity: 1 SET

- Price: Negotiable

- Packaging Details: plastic film

- Delivery Time: 50-60days

- Strap Thickness: 0.4-1.2mm

- Strap Material: PET

- Control System: PLC Control, SIMENS motor

- Product Name: PET Strap Making Machine

- Strap Speed: 250m/min

- PET packaging belt production line

- High Efficiency PET packing belt production equipment with Automatic Control

- PET plastic steel belt production equipment

- PET packing equipment

- Production equipment of bottle packaging tape

- Pack and tape equipment

Support and Services of PET packaging belt production line:

Our PET Strap Making Machine is backed by our top-notch technical support and services. We provide customer service by phone, email, and online chat. Our knowledgeable team is available to answer your questions and guide you through the product's operation. Our professional service technicians are available to provide on-site support and maintenance for the machine. We also offer annual service contracts that cover preventive maintenance, repairs, and emergency service.

We provide training for the machine operation and maintenance. Our training courses cover basic operation, safety, maintenance, and troubleshooting. We also offer on-site training for customers who prefer to have their staff trained on-site.

We also provide spare parts and accessories for the machine. We have a wide selection of spare parts and accessories available to keep the machine running at its best. We also offer a range of upgrade kits to enhance the performance and capabilities of the machine.

Packing and Shipping of PET packaging belt production line:

Packaging and Shipping

The PET Strap Making Machine is shipped in a well-sealed package to ensure the safety of the machine during transportation. The package includes the machine and all its accessories, such as the instruction manual, tools, and spare parts.

The machine is shipped via air freight, sea freight, or land freight, depending on the customer’s requirements. We provide complete tracking information for all shipments and are available for inquiries regarding the machine’s current location.

FAQ:

- Q: What is the brand name of the PET Strap Making Machine?

- A: The brand name of the PET Strap Making Machine is JIATUO CHINA.

- Q: What is the model number of the PET Strap Making Machine?

- A: The model number of the PET Strap Making Machine is JTPET.

- Q: Where is the PET Strap Making Machine made?

- A: The PET Strap Making Machine is made in China.

- Q: What certification does the PET Strap Making Machine have?

- A: The PET Strap Making Machine has an IS CEO certification.

- Q: What is the minimum order quantity for the PET Strap Making Machine?

- A: The minimum order quantity for the PET Strap Making Machine is 1 SET.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!