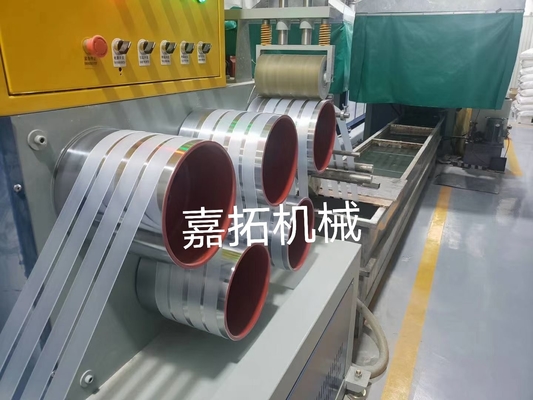

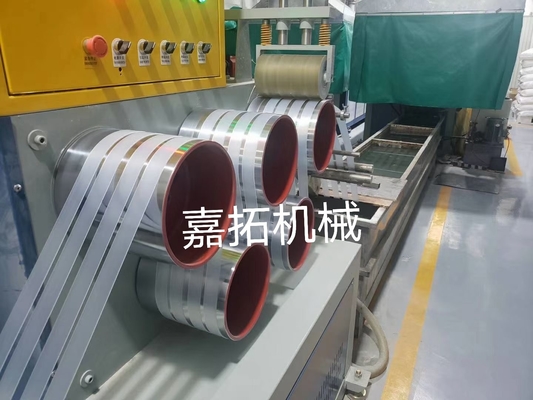

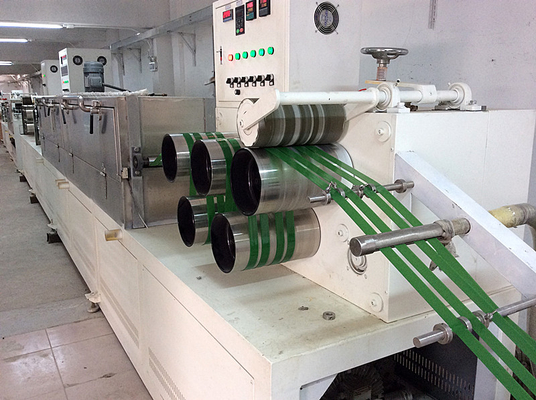

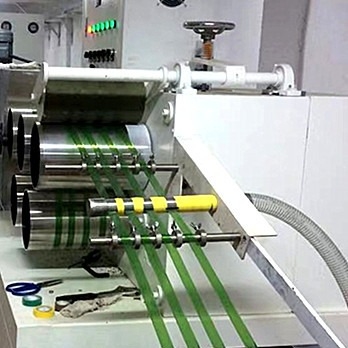

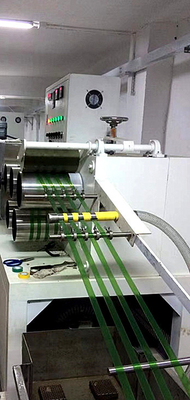

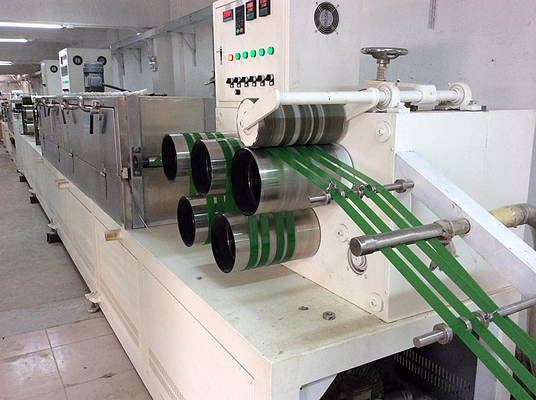

Plastic PP Pet Strapping Band Production Line Pet Packing Strap Making Machine

PRODUCT DESCRIPTION

Descripition:

This machine is mainly used to make PET strap ,PP packing strap.

Our machines adopts the PLC control to realsize the whole line auotmatic production.

Using the melting pump and pressure sensor ensure the production stable and strap quality control.

The raw material can be 100% recycled pet flakes from the waste pet bottles,or virgin material or mixed with each other.

PET Strap Production Line Machine List

| NO. |

Item |

Specification |

| 1 |

Power |

According to customer's factory voltage |

| 2 |

Material |

PET raw material or 100% PET bottle flakes recycled |

| 3 |

Capacity |

PETJT90:200kg/h

PETJT100:250kg/h

PETJT125:350kg/h

|

| 4 |

Product size |

Width:9-32mm

Thickness:0.6-12mm

|

| 6 |

Mid-height of extruder |

7000mm |

| 7 |

Installation power |

PETJT90:200KW

PETJT100:250KW

PETJT125:300KW

|

| 8 |

Humidity |

<85% |

| 9 |

Temperature |

0-40 degree |

| 10 |

Cooling tower capacity |

30T/H or 50T/H |

| 11 |

Installation Dimensions |

PETJT90:45*2.0*7.0M

PETJT100:45*2.0*7.0M

PETJT125:60*3.0*8.0M

|

| 12 |

Product color |

Green/Black/Pink/Yellow |

| 13 |

Factory dimension |

35m*(3~6)m*(4~6)m

45m*(3~6)m*(4~6)m

If your factory not big enough,please contact with us,our engineer can according to your size to design

|

Advantages of PET strap

- Use 100% Recycled PET/PP Flakes to reduce the cost.

- Good dehumidifer drying system(Crystallization system optional ) to ensure the material equal dryer to produce high quality strapping.

- Special design hot forming tensile tank to make good forming ,equal width,straight strap.

Features of PET packing strap production line:

Feature 1:

• Raw material process and extrusion system.

• High performance crystallizing and drying system.

• Production can use 100% recycled material to obtain a high add value strapping band.

Feature 2:

• Continuous back-flush screen changer operating technology (Europe technology).

• 100% full automatic self-cleaning screen changer.

• Double column 4 screen cavities.

• PLC Control , change screen without production interrupted , not influence the production quality

Feature 3:

• Special designed hot air stretching oven.

• Configured with heating unit and automatic temperature control system.High performance heat insulating layer.

• Better on strip stretching and heating, rapid heating, complete strip orientation stretching.

Feature 4:

• Heating oven for sizing

• Special designed technology, make sure the strip forming rapidly • Prevent the strip from un-orientation after orientation, eliminate internal stress,make sure the quality of strip accuracy and quality.

FAQ

1. Q: How can I purchase your goods?

A: Please choose your perfect item and tell us your size, quantity and packing you want.

2. Q: How long is the lead time?

A: Normal order within 10-30 days after deposit.

3. Q: Do you offer sample?

A: Samples can be sent for your reference, but charge is required, after making formal order, the cost of samples will be cut from the total amount.

4.Q: What is the MOQ on your products?

A: Small quantity can be acceptable, depends on the stock.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!