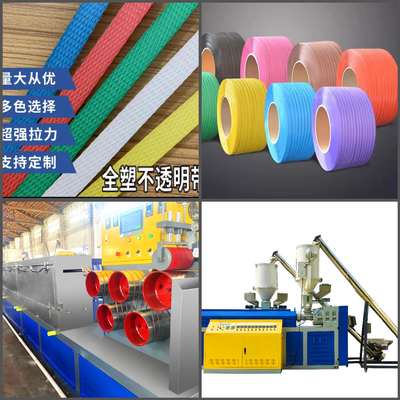

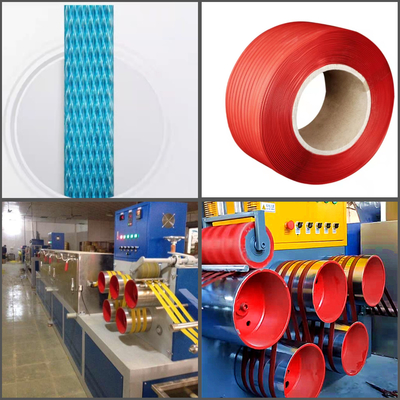

PP Plastic Packing Strap Macking Machine Packing Strapping Belt Production Machine

Description of PP packing belt making machines, PP packing strap extrusion machine

PP packing strip is widely used in packing applications, it can replaced the steel strap for packing application, as its good tensile strength, flexible, low prolongation rate, good performance of high temperature resistant, non-rustiness, and low use-cost, etc, it is used in steel, construction material, chemical fiber, paper making, tobacco, agriculture, election, etc.

Parameter of PP strap making machine

| Power supply |

380V, 50Hz, 3Phase (according to customer requirement) |

| Raw material |

PP material |

| Width of final product |

5-19mm |

| thickness of final product |

0.4-1.2mm |

| Max Capacity |

110-150kg/hour |

| Manpower |

2-3 persons/shift (fully-auto just need one) |

| Machine Dimension |

L (28m) ×W (2m) ×H (4m) |

| BRANDS |

| Motor |

Siemens |

| Gearbox |

Shenzhen Beiji |

| Contactor |

Taiwan Fotek |

| Temperature controller |

Schneider |

| Inverter |

INVT |

System Configuration of Output 2 Straps Production line

※ Vacuum feeder 1 set

※ Hopper dryer 1 set

※ Feeding machine 2 set

※ ¢90 Extruding Machine 1 set

※ Automatic Screen filter changer 1 set

※ Mould(1 mould for 2 output) 1 set

※ Water cooling tank system 1 set

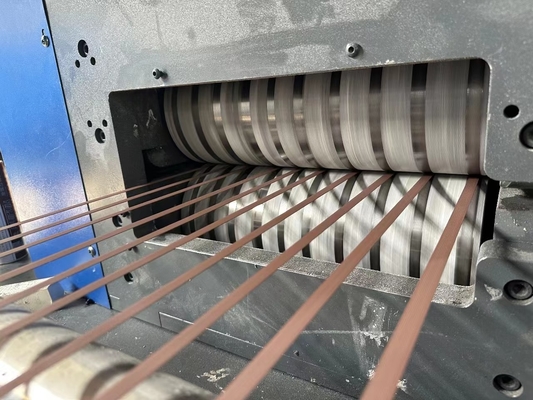

※ The first haul-off device 1 set

※ Stretching oven 1 set

※ The second haul-off device 1 set

※ PLC electrical control system 1 set

※ Embossing machine 1 set

※ Forming oven 1 set

※ Cooling system 1 set

※ The third haul-off device 1 set

※ Double disk winder 2 set

Advantage of JIATUO PP packing belt making machines, PP packing strap extrusion machine

- Special design of the screw extrusion technology can be choosing as per customer needs.

- Can process 100% recycled PP/PET bottle flakes or pellets.

- Plasticization and stable extrusion can with PLC automatic control for the full line.

- According different requirements, changing materials for make strap have better and special function. For example, the strap for packing cotton can be from enhancing the breaking strength and joint strength when welding strap.

- Melt filter with two pistons with air venting design and back flushing.

- Number of strap:2,3,4,6,8 Width: 5mm-19mm,Thickness: 0.4mm-1.2mm

- Workers: 2 -3 workers per shift, 12 hours/shift, if change the fully automatic winder can just need one person to operate.

Best Services

- The guarantee period is 1 year and service is available lifelong.

- Our expert will answer any inquiry within 24-48 hours and it will be solved as soon as possible.

- Our company supplies the complete technical support documents and the relative drawings of the electric components written in Chinese and English.

- Our company shall send enough technicians to the Buyer's company for installation, debugging, training and technology transfer till customers can operate independently and manufactures eligible product.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!