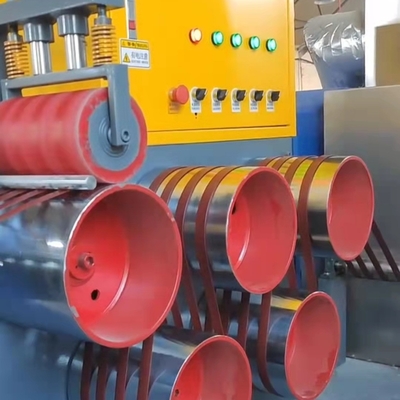

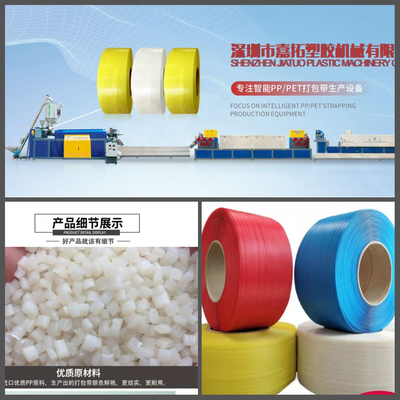

Recycled PP 2 Cavity Strap Making Machine Plastic Packaging Machine

Quick Detail Of PP Strap Making Machine

PP strap production line is used to produce mechanical or manual bands with 100% PP recycled granules as materials, if raw materials, it will be better. This kind of band is widely used in the packing of kinds of fields such as mines, general merchandise, weaving, electrical equipment, apparatus, architecture, medicine, etc.

Specification Of PP Strap Production Line

| Output |

150kg/hr |

300kg/hr |

500kg/hr |

800kg/hr |

| Motor Power |

55KW |

110KW |

160KW |

250KW |

| Installation Power |

280KW |

445KW |

635KW |

900KW |

| Speed |

120m/min |

120m/min |

120m/min |

120m/min |

| Overall Size of Machine |

32*4*5m |

46*5*5.5m |

60*6*6m |

60*6*6m |

| Width of Strap |

9-19mm |

9-32mm |

9-32mm |

9-32mm |

| Width Tolerance |

±0.45mm (int. ±0.76mm) |

| Thickness of Strap |

0.55~ 1.27mm |

0.55~1.27mm |

0.55~1.27mm |

0.55~1.27mm |

| Thickness Tolerance |

±0.05mm (int. ±0.06mm) |

| Elongation Rate of Strap |

10~15% |

| Breaking Strength of Strap |

< 50kg/mm² |

Features Of Plastic PP Extrusion Line

Features Of Plastic PP Extrusion Line(1) Safety and environmental protection:safe for use, not easy to hurt, according with EU environmental directives, for example ROSH.

(2) Low cost:It is the most cost-effective in new environmentally friendly packaging materials products.

(3) Easy to use:Suitable for fully automatic balers, manual balers and other packaging machinery quickly and convenient to use.

(4) Excellent toughness: Between -50 ~ 100 ºC temperature, it is fully capable of normal use, and maintains excellent flexibility.

(5) Look beautiful: Finish bundled items look beautiful, does not pollute the items, never rust.

(6) Very good strength: Can provide up to 470 MPA tensile strength to protect the safety of Strapping.

FAQ ABOUT PP STRAPPING BAND EXTRUSION LINE

1. For PP(polypropylene) strapping band extrusion line

* What about the output of PP strapping band extrusion line? 150kg/hr, 280kg/hr, 500kg/hr.

* What about the size of strap that the PP strap machine can make? Width: 5-25mm; Thickness: 0.35-1.0mm;

* What about the installation power of the PP strap machine? 135kw/155kw/195kw/439kw;

2. For PET(polyester) strapping band extrusion line

* What about the output of PET strapping band extrusion line? 200kg/hr, 400kg/hr, 600kg/hr, 800kg/hr.

* What about the size of strap that the PET strap machine can make? Width: 9-32mm; Thickness: 0.35-1.2mm;

* What about the installation power of the PET strap machine? 215kw/285kw/352kw/900kw;

Advantages Of PP Extursion Making Machine

1.Special design of the screw extrusion technology can be choosing as per customer needs.

2.Can process 100% recycled PP/PET bottle flakes or pellets.

3.Plasticization and stable extrusion can with PLC automatic control for the full line.

4.According different requirements, changing materials for make strap have better and special function. For example, the strap for packing cotton can be from enhancing the breaking strength and joint strength when welding strap.

5.Melt filter with two pistons with air venting design and back flushing.

6.Number of strap:1,2,4,6,Width: 5mm-22mm,Thickness: 0.5mm-1.5mm

7.Workers: 2 -3 workers per shift, 12 hours/shift.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!