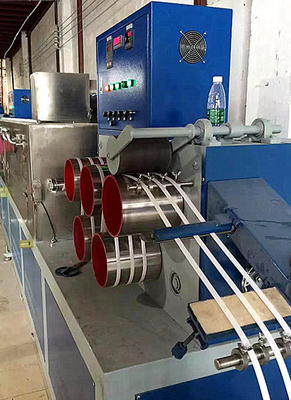

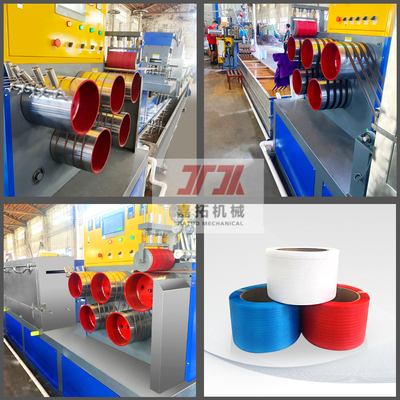

Fully Automatic PLC Control JiaTuo PP Strap making Machine with GUOMAO Motor

Description of PP strap band production machine

PP strap production line is used to produce mechanical or manual bands with 100% PP recycled granules as materials, if raw materials, it will have better for the final PP strapping. This kind of band is widely used in the packing of kinds of fields such as mines, general merchandise, weaving, electrical equipment, apparatus, architecture, medicine, etc. when use of the PP strapping to packing it is more convenient to operate with a packing machine.

Main technical parameters of PP strap production machine

| Type |

JTPP-90 |

JTPP-100 |

JTPP-110 |

JTPP-125 |

JTPP-135 |

JTPP-90/65 |

JTPP110/75 |

| Strap of number |

2 |

3 |

4 |

6 |

8 |

2

Sandwich belt

|

4

Sandwich belt

|

| width |

5-19mm |

5-19mm |

5-19mm |

9-19mm |

9-19mm |

9-19mm |

9-19mm |

| Thickness |

0.6-1.2mm |

| Reducer mode |

200 |

200 |

225 |

250 |

280 |

200/173 |

225/173 |

| Screen changer |

Automatic/ Manual |

| Production capacity |

80-120kg/H |

180-200kg/H |

220-250kg/H |

350-370kg/H |

460-500kg/H |

80-120kg/H |

180-200kg/H |

| Screw type |

Single screw |

Double screw |

Process flow of PP packing belt production line

① Feeding →② stirring →③ pre-drying →④ melting and measuring extrusion →⑤ embryo (belt embryo) cooling and forming →⑥ oven preheating →⑦ primary stretching →⑧ secondary stretching →⑨ embossening →⑩ oven tempering and setting →⑪ cooling →⑫ finished product winding

Remarks: If there is a printing machine after the second stretching first printed and then embossed in item 8.

Machine advantages of PP strap making machine

This line is specially designed for the production of PP Straps. It can produce 2/3/4/6/8 PP Straps at the same time (depending on how much PP straps you want it produce in the same time) that saves energy by 20%-30%,

PLC Controller by touching keys with Chinese and English languages, which is safe and easy to operate that keeps good status of all, can remember all the parameter what you production before yet to keep the belt quality in stable.

Special high-efficiency all stain steel heating tube, rapid heating and durable in the part of stretch oven.

All the electrical use of the famous brand to keep our machine safe oprate, and longer warranty for you.

FAQ

Q:What is the voltage of PP strapping equipment?

A:380V/50HZ, we support customization

Q:Can the PP strapping production equipment be customized according to the factory length?

A:Yes, we can customize the length according to the customer's factory size.

Q:Where is the PP strapping equipment produced?

A:We are from China.

Q:Can PP strapping equipment provide after-sales service?

A:Yes, we have professional after-sales engineers who provide 24-hour online guidance.

Q:Is the quality of PP strapping equipment stable?

A:We have 30 years of manufacturing experience, and have their own PP packaging belt production plant, equipment quality is stable, the process is worth choosing.

Q:Does PP strapping equipment support customization?

A:We are a manufacturing plant that can customize model size, extrusion capacity, voltage and so on according to customer requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!