PET Strapping Band Production Line Plastic Strap making machine with PLC Control

PET PACKAGING BELT EXTRUDING MACHINE DESCRIPTION

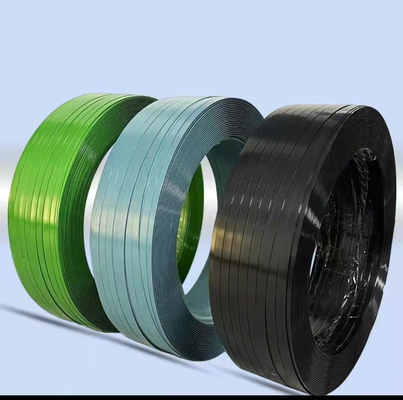

PET packing strap is widely used, replaced for steel strap for packing application internationally, because of its good tensile strength, flexible, low prolongation rate, good performance of high temperature resistant, non-rustiness, and low use-cost, etc, it is used in steel, construction material, chemical fiber, paper making, tobacco, agriculture, election, etc.

PET Strap Production Line Machine List

| NO. |

Item |

Specification |

| 1 |

Power |

According to customer's factory voltage |

| 2 |

Material |

PET raw material or 100% PET bottle flakes recycled |

| 3 |

Capacity |

PETJT90:200kg/h

PETJT100:250kg/h

PETJT125:350kg/h

|

| 4 |

Product size |

Width:9-32mm

Thickness:0.6-12mm

|

| 6 |

Mid-height of extruder |

7000mm |

| 7 |

Installation power |

PETJT90:200KW

PETJT100:250KW

PETJT125:300KW

|

| 8 |

Humidity |

<85% |

| 9 |

Temperature |

0-40 degree |

| 10 |

Cooling tower capacity |

30T/H or 50T/H |

| 11 |

Installation Dimensions |

PETJT90:45*2.0*7.0M

PETJT100:45*2.0*7.0M

PETJT125:60*3.0*8.0M

|

| 12 |

Product color |

Green/Black/Pink/Yellow |

| 13 |

Factory dimension |

35m*(3~6)m*(4~6)m

45m*(3~6)m*(4~6)m

If your factory not big enough,please contact with us,our engineer can according to your size to design

|

Features of PET packing strap production line:

1. The raw material treatment is by our serious dehumidify and dryness system, it ensures the humidity in raw material less than 80PPM.

2. Closed circulation feeding system prevent the material from exposure on air to keep the dryness of raw material.

3. The screw is specially designed for PET application, it consists of separate and mixing part to keep the even plastication, also by fixed material feeding system, the extrusion is stable, which ensures the good dimension of PET strap.

4. The machine can produce 1/2/4 strap at the same time.

5. The mould is specially designed, equipped with two-stage filter.

6. Constant temperature heating device provide even cooling environment for PET strap to raise the tensile strength performance.

7. Anneal treatment for finished PET strap to remove the part remaining stress to keep good shape.

FAQ

1. Q: How can I purchase your goods?

A: Please choose your perfect item and tell us your size, quantity and packing you want.

2. Q: How long is the lead time?

A: Normal order within 10-30 days after deposit.

3. Q: Do you offer sample?

A: Samples can be sent for your reference, but charge is required, after making formal order, the cost of samples will be cut from the total amount.

4.Q: What is the MOQ on your products?

A: Small quantity can be acceptable, depends on the stock.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!