9-25mm PET plastic steel belt equipment Pet Packing Tape Equipment Strap Making Machine

PRODUCT DESCRIPTION ABOUT PET PLASTIC BELT EQUIPMENT

PET plastic steel belt equipment Function and Advantage:

High tensile strength, limited elongation, good impact resistance, economic, convenient operation and safety. It is an ideal substitution of traditional steel strap.

Packing for paper, wood, cotton, fiber, metal, aluminum-plastic profile products and various pallets.

Features PET plastic steel belt equipment:

1, Special twin screw extrusion technology and single screw extrusion technology, can be choose as per customer needs

2, Process 100% recycled PET bottle flakes( After Grace-M PET washing and recycling line)

3, Even plasticization and stable extrusion with PC automatic control for the full line

4, As per different requirements, changing A coating materials for make strap have better and special function. Foe example, the strap for packing cotton, can be from enhancing the breaking strength and joint strength when welding strap

5, Melt filter with two pistons with air venting design and backflusing

6, Number of strap: 1, 2, 4, 6

PET plastic steel belt equipment (Related parameters)

| Item |

Quantity |

| 1.Lifting mixing drying system and screw feeding system |

1 set |

| 2.450 type dehumidifier and drying crystallization tank |

1 set |

| 3. single screw extruder |

1 set |

| 4.high-power screen changer |

1 set |

| 5.metering pump with independent speed regulation system |

1 set |

| 6.Special mould for PET strap band |

1 set |

| 7.Cooling water tank |

1 set |

| 8.The first five-roller tractor |

1 set |

| 9.Stretching oven |

1 set |

| 10.The second five-roller tractor |

1 set |

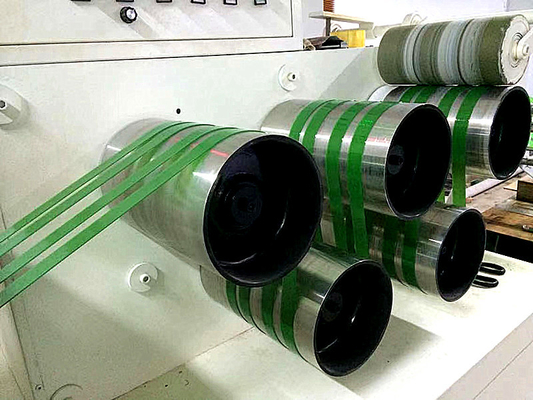

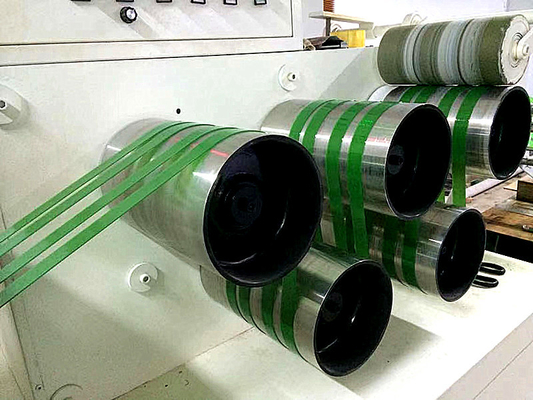

| 11.Embossing machine |

1 set |

| 12.The third five-roller tractor |

1 set |

| 13.Cooling sizing system |

1 set |

| 14.The fourth three-roller tractor |

1 set |

| 15.Single station semi-automatic winding machine |

1 set |

Features of PET plastic steel belt production line:

Efficient production-----with high degree of automation and fast production speed.

High-quality products----The produced PET plastic steel belt has high strength, good toughness and strong tensile force.

Energy saving -----energy-saving design is adopted, the raw materials are mineral water bottles, which can be recycled and the manufacturing cost is low.

Easy operation----PLC automatic control, easy to operate.

ABOUT US

We have nearly 30 years of production experience in the production of PP PET strapping equipment. We have our own production workshop, processing center, high-precision imported lathes, sales team, after-sales team, management team, etc.; including we currently also produce PP strapping, PET plastic steel strapping, etc., so we are very clear about the process details, the formula ratio of raw materials, and the addition ratio of various auxiliary materials;

We are the agent for the sale of various automatic strapping machines, semi-automatic strapping machines, handheld strapping machines, pneumatic strapping machines, etc., so we are clear about the requirements of different strapping machines for strapping;

We currently have 3 factories:

PP PET strapping equipment factory: 1PCS

PET plastic steel strapping factory: 1PCS

PP strapping factory: 1PCS

FQA:

Q: What is the voltage of the PET plastic steel belt equipment?

A: 380V/50HZ, three-phase (customization supported)

Q: What is the extrusion capacity of the PET plastic steel belt equipment?

A: Different models have different extrusion capacities, with capacities ranging from 150-600KG/H

Q: What is the producible width of the PET plastic steel belt equipment?

A: 9-32mm

Q: Can the PET plastic steel belt equipment be customized?

A: Customization supported

Q: Where does the PET plastic steel belt equipment come from?

A: China.

Q: What are the certifications for the PET plastic steel belt equipment?

A: ISO CEO certification.

Q: What is the minimum order quantity for the PET plastic steel belt equipment?

A: 1 set

Q: What is the weight of the PET plastic steel belt equipment?

20T, 40GP container * 3PCS

The winder could be designed into servo motor unit, inverter motor unit and torque motor according PET or PP materials.

The unique back tooth shaft is used to make the packing belts neatly arranged without overlapping and no horn shape, so that the packing belts maintain a good straightness, which is more suitable for the use of automatic packing machines, and ensures that the automatic equipment conveyor belts are in place. Do not drop the belt.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!